Executive summary

This 2D Barcodes at Retail Point-of-Sale Implementation Guideline is focused on the considerations and implications of utilising 2D barcodes encoded with GS1 barcode syntaxes at retail point-of-sale (POS) for brand owners, manufacturers, retailers and solution providers. The purpose of this document is to provide implementation guidance for industry to use in their 2D barcode journey and to enable a smooth, voluntary transition from linear barcodes, to using more capable 2D barcodes while minimising disruptions to existing business processes.

The changing landscape of the retail industry

To better enable the digital consumer and unlock current and emerging business use cases, such as sustainability and circular economies, the retail industry is embarking on one of the biggest changes since the original introduction of the EAN/UPC barcode: the adoption of 2D barcodes. 2D barcodes, like GS1 DataMatrix, Data Matrix or QR Codes, can be encoded with more data than the EAN/UPC linear barcode. Within these 2D barcodes, both additional data and links to web-enabled information can be included through the use of GS1 Digital Link URI in Data Matrix and QR Codes. Data might, for example, include the product’s expiry date, batch/lot number or serial number. Additionally, access to additional information on the web can include ingredient and allergen information, product pictures and videos, consumer reviews, recycling information services related to the product and more. Access to this additional information and data enhances the experiences of consumers, brands, retailers and everyone in between.

Ambition 2027

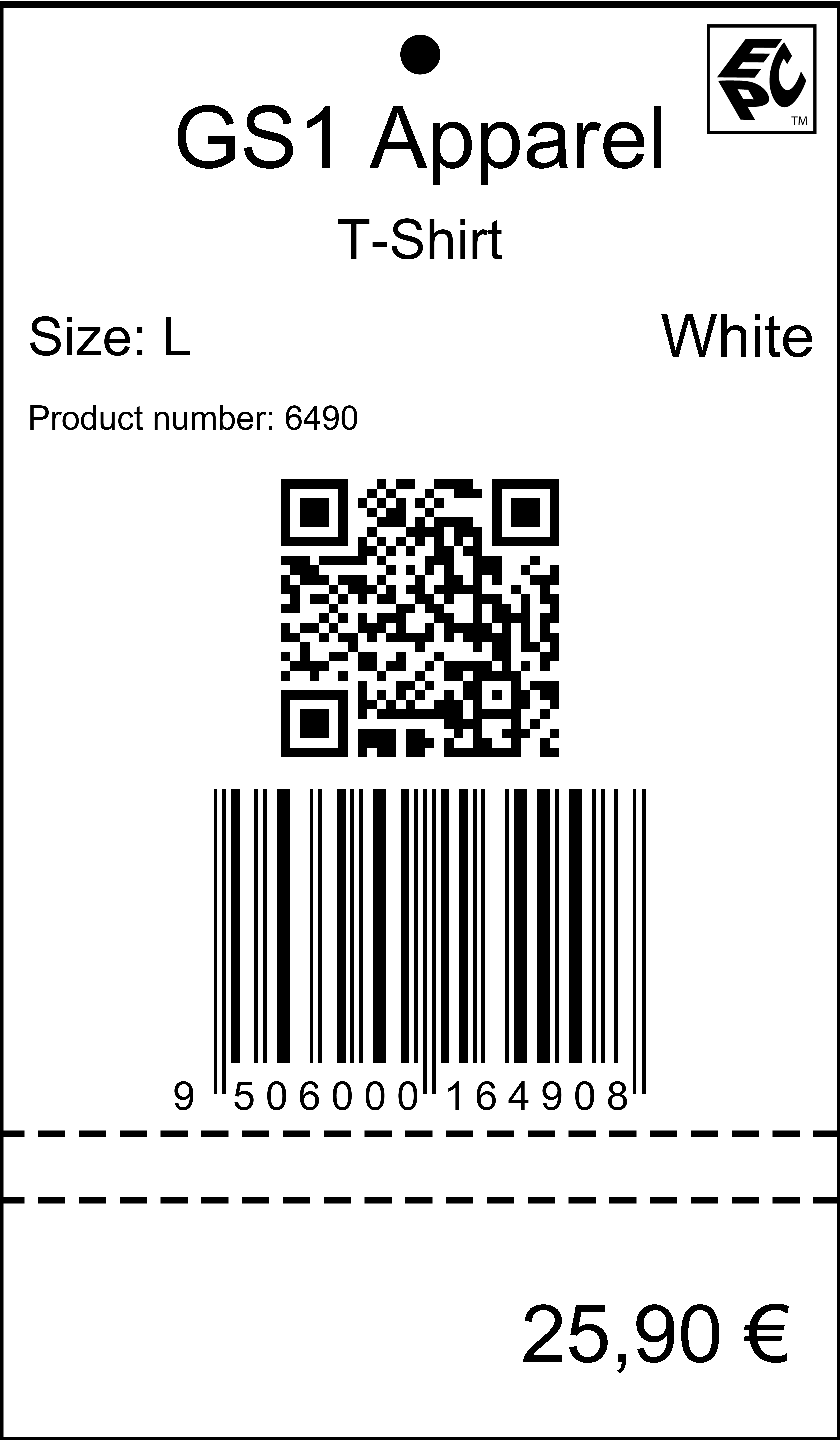

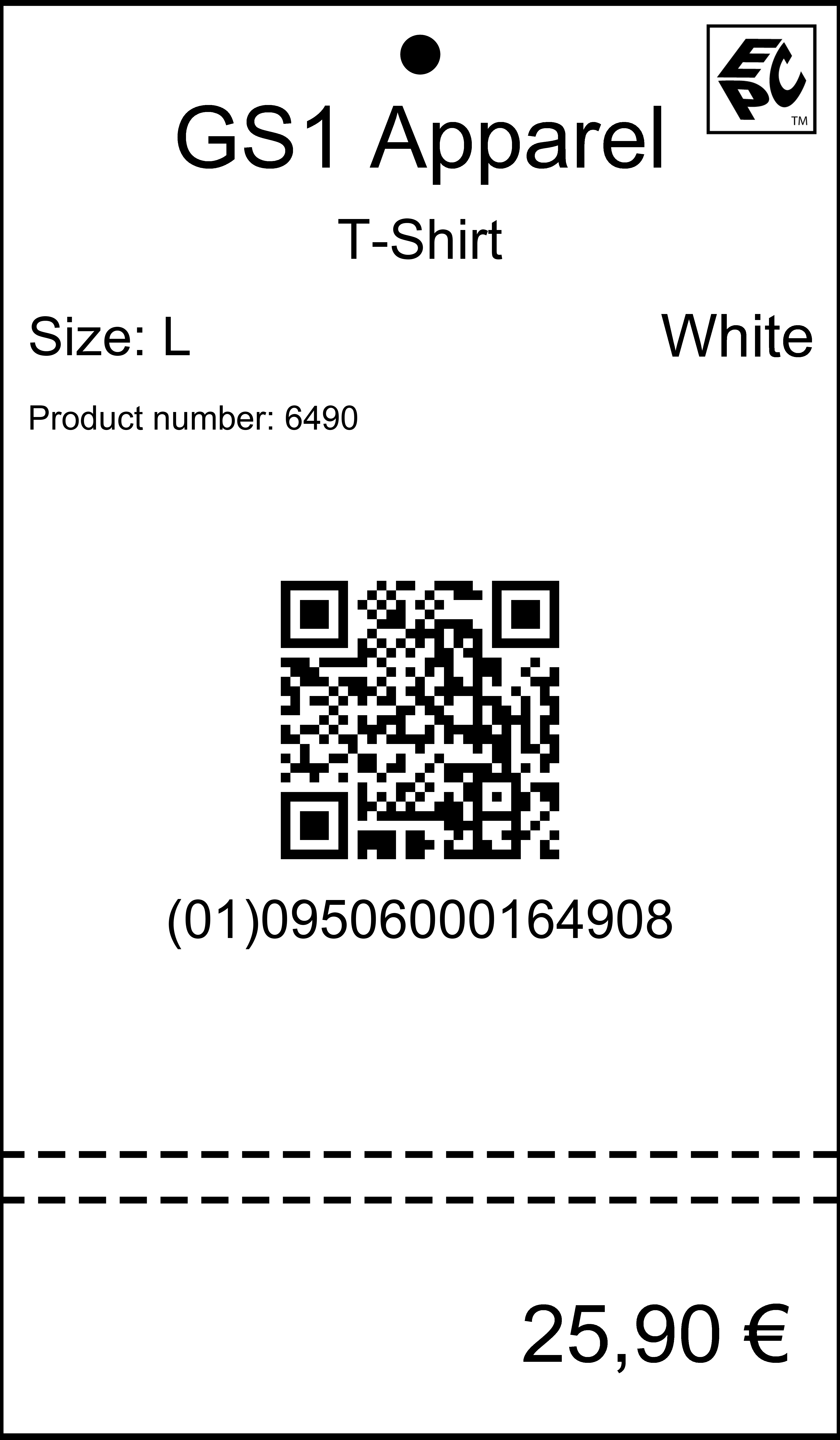

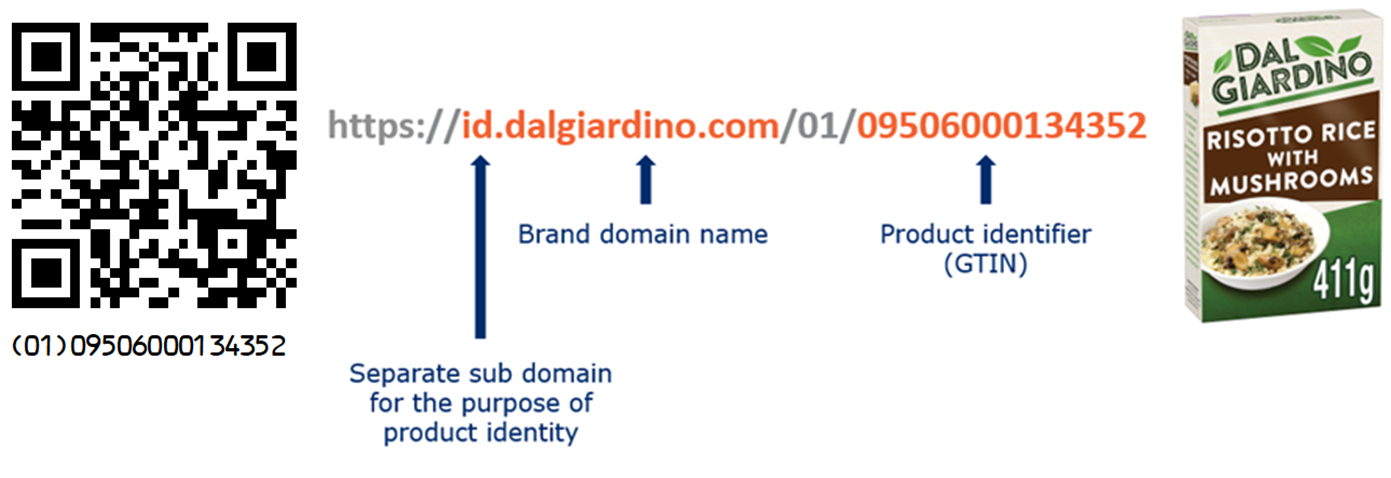

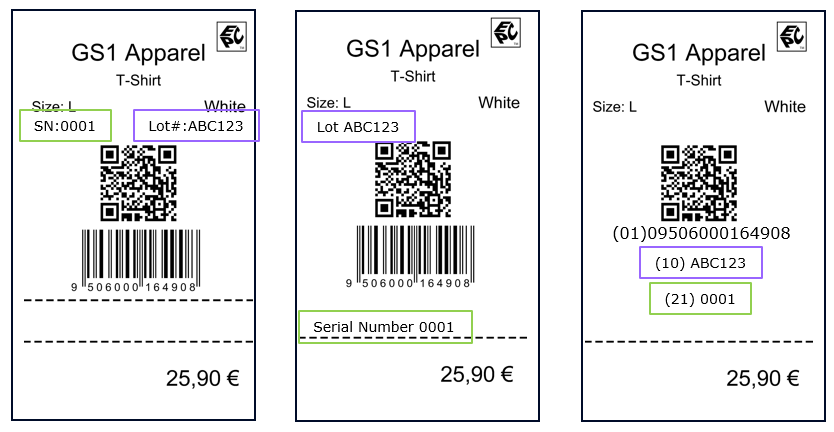

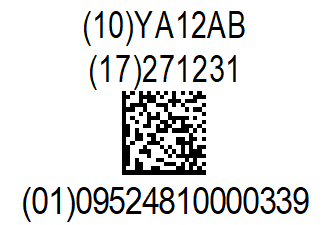

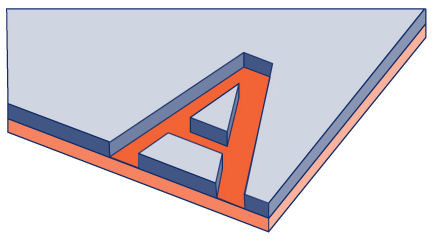

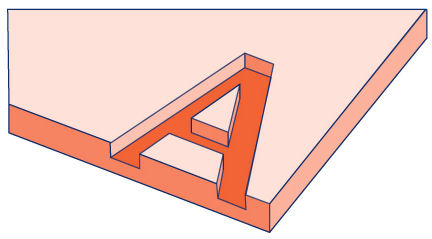

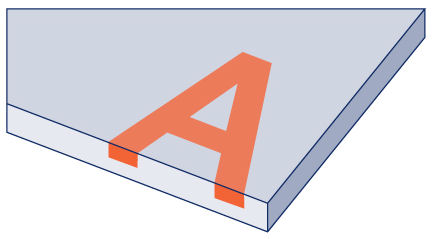

Industry has set the ambitious goal of transitioning from linear, 1D barcodes to more capable 2D barcodes on-pack. The initial goal is for retail point-of-sale (POS) scanning to be globally capable of reading and processing the GTIN from both existing linear and 2D barcodes by the end of 2027. The Ambition 2027 will require software upgrades and may require equipment upgrades if the POS scanner is not already imager capable. GS1 and industry are working together to support this migration and generate globally consistent guidance for business use cases. As there is no expectation that there will be a single 2D barcode selected for all industries, GS1 standards are enabling options that empower each industry to choose how they evolve towards more capable 2D barcodes while ensuring globally consistent implementations now and in the future. For example, in healthcare the journey towards 2D started in the early 2000s when industry chose GS1 DataMatrix as the single 2D barcode for product identification. Today there are billions of product packs with GS1 DataMatrix encoding the GS1 element string syntax. For healthcare products GS1 DataMatrix is the 2D barcode of choice for point-of-sale scanning. Linear barcodes (e.g., EAN/UPC and GS1 DataBar) will not go away and will coexist with 2D barcodes for as long as there are uses for them. During the dual-marking transition phase, the trade item will feature both the current linear (i.e., EAN/UPC or GS1 DataBar retail POS family) barcode and either a GS1 DataMatrix or QR Code with GS1 Digital Link URI syntax, or a Data Matrix with GS1 Digital Link URI syntax. For more information on the retail 2D barcode see section 4.1. Figure 1-1 illustrates how to use a 2D barcode in addition to the linear barcode for companies and users who are ready to unlock opportunities enabled by 2D showing the minimum human readable interpretation (HRI) for retail.

Note: Once 2D barcodes at POS have achieved pervasive adoption, brand owners and manufacturers can choose to use only the 2D barcode, continue with the retail POS linear barcode in combination with the 2D barcode or stay with only the POS linear barcode.

Note: Not all imaging scanners will be capable of the Ambition 2027 goal, therefore collaborating with the point-of-sale solution provider will be essential for accepting 2D barcodes at POS. See section 7.5.1 2D in retail barcode scanning considerations for more information.

For further information, contact your local GS1 Member Organisation.

About this document

This is a practical implementation guideline for brands, manufacturers, retailers, suppliers, distributors, warehouse operators and solution providers to understand business opportunities, process changes and requirements needed to implement GTIN, GS1 Application Identifiers (AIs), GS1 DataMatrix, GS1 Digital Link URI syntax in QR Code or Data Matrix and linear barcodes at point-of-sale (POS) and in manufacture of trade items.

All barcode examples in this document, are shown for illustrative purposes only and may not represent the sizes approved for use in the GS1 General Specifications. The Symbol Specifications Tables defined by the GS1 General Specifications SHALL be used for all normative references to ensure conformance requirements are met.

This document includes information designed to help companies plan for 2D implementations. Sections 2 through 4 are focused on definitions and explanations, including:

- Retail POS barcodes

- Choosing the right barcode

- Benefits of GTIN and additional data

- GS1 barcode structures

All readers are advised to read section 4 for general guidance.

- New users: If GS1 standards are new to your company, please contact your local GS1 Member Organisation (www.gs1.org/contact).

- Brands and manufacturers: Read section 5 for business process changes required to implement GTIN, GS1 Application Identifiers, GS1 barcode syntaxes and conformant GS1 barcodes at point-of-sale. Read section 7 for guidance on enabling 2D capability within a brand and manufacturer’s ecosystem.

- Retailers: Read section 6 for business process changes required to implement GTIN, GS1 Application Identifiers, GS1 barcode syntaxes and conformant GS1 barcodes at point-of-sale. Read section 5 for private label guidance and section 7 for guidance on enabling 2D capability within a retailer ecosystem.

- AIDC equipment and software companies: Read section 7 and 8 for requirements to implement GTIN, GS1 Application Identifiers, GS1 barcode syntaxes and relevant GS1 barcodes at point-of-sale.

Sections 5 through 8 are focused on implementation guidance for manufacturers and brand owners, retailers, distributors, warehouse operators and solution providers. While the information provided is not intended to enable a complete 2D implementation across a company, it can be used as a resource alongside the GS1 General Specifications, with guidance from local Member Organisations for companies to reference along their journey.

The final appendix sections focus on information to successfully print 2D barcodes during the transition period until the required capabilities are achieved.

Background

The Universal Product Code barcode (UPC-A and UPC-E) and European Article Number barcode (EAN-13 and EAN-8) have been trusted and ubiquitous data carriers for facilitating the price look-up function at retail point-of-sale (POS) since the early 1970s. This innovation automated a critical business process for retail POS everywhere.

The EAN/UPC family of barcodes carries only the Global Trade Item Number® (GTIN®) associated with a product. Due to this data capacity limitation, the GS1 DataBar Expanded barcodes were introduced to meet business requirements for more data, such as batch/lot number and expiration date. However, GS1DataBar Expanded barcodes still have limited data capacity, and can become too large to fit on many packages. As linear barcodes require a mobile device app to access online information, they are not as consumer friendly as other data carriers, such as QR Codes, that allow consumers and business users alike to access additional product data and online information more directly.

The momentum for change, to use more capable 2D barcodes, is driven by industry’s need to encode more data on-pack and to allow consumer engagement through links to web-enabled information. This meets the growing information demands of consumers and regulators, enables additional supply chain efficiencies, creates new circular economies and builds brand trust by providing more accurate, complete and up-to-date product information, all the while enabling existing POS processes.

Purpose

The purpose of this document is to provide implementation guidance for industry beginning their 2D barcode journey and to enable a smooth, voluntary transition from using linear barcodes to using more capable 2D barcodes while minimising disruptions to existing business processes. This 2D Barcodes at Retail Point-of-Sale Implementation Guideline is focused primarily on the considerations and implications of utilising 2D barcodes encoded with interoperable GS1 data and syntaxes at point-of-sale (POS).

This document is expected to expand over time based on growing user implementations and as the standards are updated.

Scope

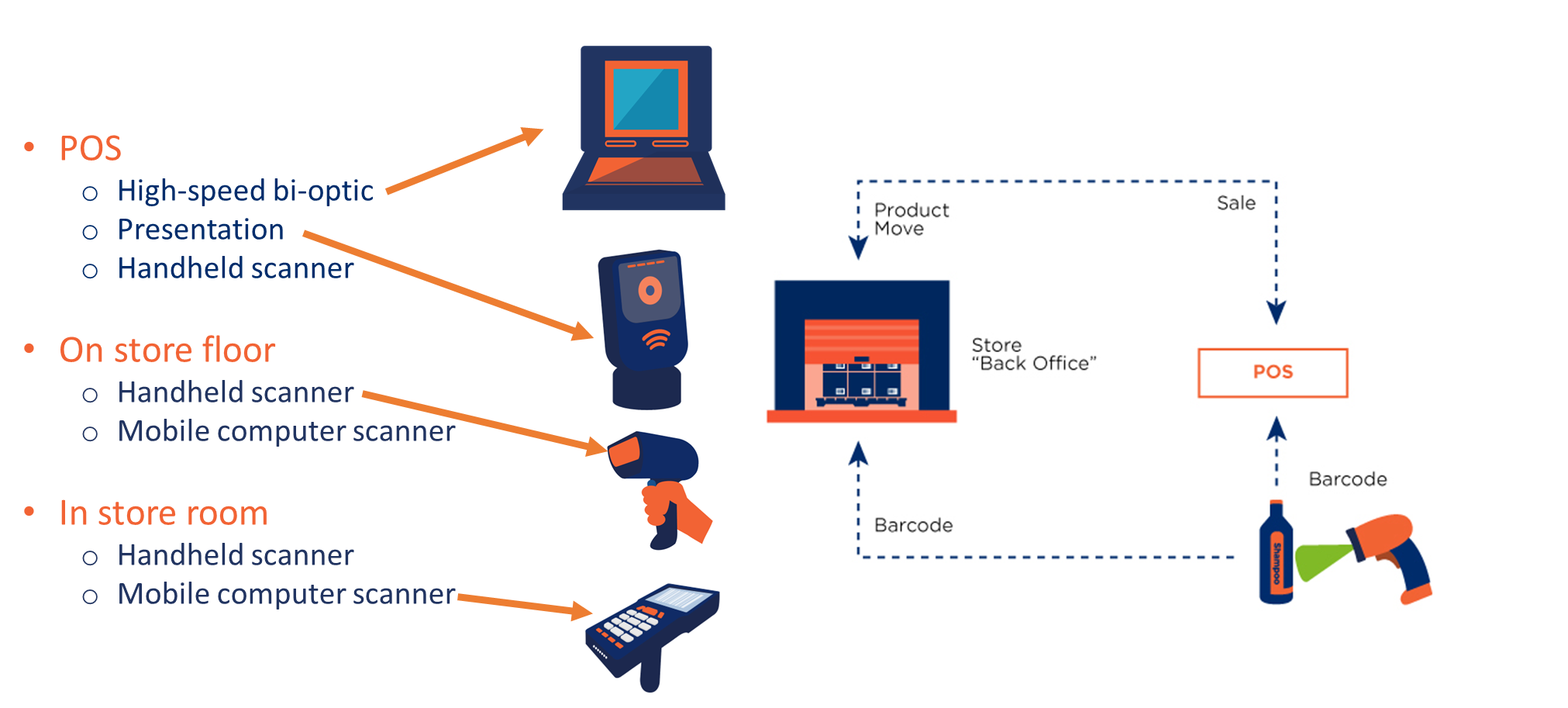

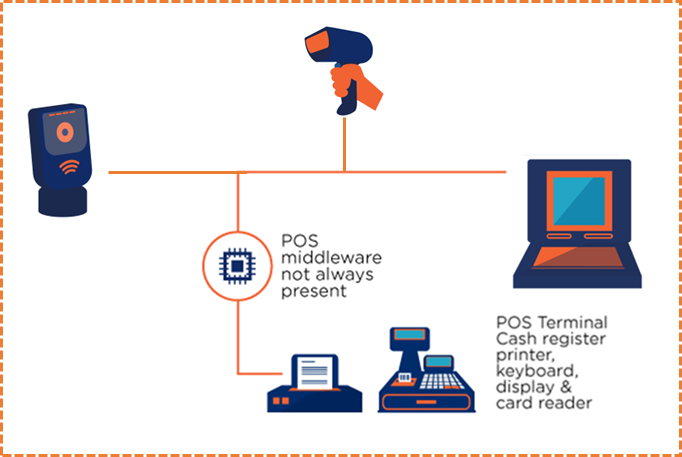

* While point-of-sale (POS) is mainly referred to as being enabled by fixed or hand-held scanners at the front of the store, retail POS can happen in multiple locations and ways, including utilising scanners in POS lanes, at self-checkout or using mobile devices on the sales floor and the backroom.

** RFID data carriers that use GS1 standards are seeing increasing use in supply chain to improve inventory management - especially in the apparel sector - they will not be addressed in this document. For more information on RFID, see EPC/RFID standards and guidance.

*** This 2D Barcodes at Retail Point-of-Sale Implementation Guideline is not an exhaustive implementation guideline for all regulated healthcare uses cases for GS1 DataMatrix. It includes guidance for healthcare products intended to be scanned at point-of-sale. For details on the use of GS1 DataMatrix for regulated healthcare products, see the GS1 DataMatrix Position Paper. A full list of global GS1 healthcare position papers can be found at https://www.gs1.org/industries/healthcare/position-papers.

Important: Products may exist in multiple channels (e.g., retail and foodservice, clinical healthcare settings). This document only addresses scanning at POS in retail channels.

Terms, definitions, abbreviations and placeholders

Terms and definitions (Glossary)

Please refer to the https://xchange.gs1.org/sites/glossary/ for the latest version.

Abbreviated terms

Placeholders

A placeholder serves as a temporary word or symbol until actual data is provided in the application.

General guidance

This section provides information that may be used by any retail sector stakeholder looking to implement 2D barcodes and assumes a basic understanding of the GS1 system. Before beginning implementation of 2D barcodes or additional data capture, it is highly recommended that stakeholders gain an initial understanding of the GS1 system of standards related to product identification and data capture, by working with their local GS1 Member Organisation (www.gs1.org/contact).

For further education on GS1 standards, see GS1 General Specifications, GS1 two-dimensional (2D) barcodes, GS1 DataMatrix Guideline, GS1 Digital Link URI Standard and The key role of GS1 DataMatrix barcodes for product identification in healthcare.

Retail POS compliant barcodes

Retailers, brands, solution providers and GS1 collaborated to reach consensus on the future of barcodes in retail. The resulting GS1 barcode standards and guidance provide the size, quality, placement, syntax and human readable text criteria for 2D barcodes used on retail consumer trade items scanned at point-of-sale (POS).

While the POS linear barcode is not going away, 2D barcodes cannot immediately be the only barcode on-pack until ubiquitous global scanning of 2D barcodes is achieved. Therefore, industry needs a transition period. The new standards and Ambition 2027 allow retailers and other parties throughout the supply chain time to plan for being able to scan and process different barcodes through their POS and facilities. With planning, this will ensure the ability to support the evolution of existing systems to unlock these additional capabilities by 2027.

Until 90% of POS scanning solutions are capable of using GS1 compliant POS 2D barcodes and at minimum capture the GTIN, any products using retail 2D barcodes on-pack will need to be accompanied by a POS linear barcode.

Retail barcodes options

The point-of-sale (POS) linear barcode choices include the EAN/UPC and GS1 DataBar POS family of barcodes.

| EAN-13 | GS1 DataBar Expanded Stack |

|  |

The POS 2D barcode choices, for future state implementations including the transition period, are the QR Code with GS1 Digital Link URI syntax, Data Matrix with GS1 Digital Link URI syntax and GS1 DataMatrix.

| QR Code (GS1 Digital Link URI) | GS1 DataMatrix |

|  |

Important: Once 2D barcodes at POS have achieved pervasive adoption the brand owner can choose to use only the 2D barcode, continue with the retail POS linear barcode in combination with the 2D barcode or stay with only the POS linear barcode.

The GS1 General Specifications has a section devoted to Application Standard Profiles (ASP) that helps navigate adopting 2D barcodes. The ASPs provide an overview of what is conformant for current and future state implementations to facilitate the transition period. These ASPs are designed for all stakeholders involved in the implementation process to access the application standards, barcode choices, barcode standards (e.g., ISO specifications, X-dimension, size, quality specifications), barcode syntaxes and more.

Placement and multiple barcodes

Placement of 2D barcodes and the rules for multiple barcodes on-pack are critical to ensure POS remains efficient. Without these rules, high speed retail point-of-sale (POS) may be unable to meet their productivity target rate of 40 to 70 items per minute (IPM). Section 4.15 of the GS1 General Specifications provides a set of barcode management practices intended to permit the use of multiple barcodes on the same trade item. This includes rules for adjacent and non-adjacent placement and rules for the transition to 2D barcodes. Also see section 5.5.1 Dual-marking with a linear and 2D barcode.

In parallel, several POS scanner solution providers have developed software for some models of their POS solutions to manage multiple barcodes on-pack. Their new software can decode multiple barcodes and deliver the encoded data from barcodes leveraging GS1 identification, as well as delivering the information as a GS1 element string syntax to the host POS system. This is important for situations when a barcode with GS1 Digital Link URI is identified, because translating the URI syntax to a GS1 element string syntax eliminates the need to upgrade the host POS system to scan GS1 Digital Link URI syntax. However, to achieve the 40 to 70 IPM target, the placement of linear and 2D barcodes relative to each other needed to be determined through extensive lab testing. See also 2D in Retail co-located test results for details.

Important: Not all POS solutions are capable of processing GS1 compliant 2D barcodes at this time. It is best to contact the solution provider to confirm capabilities on specific POS solutions.

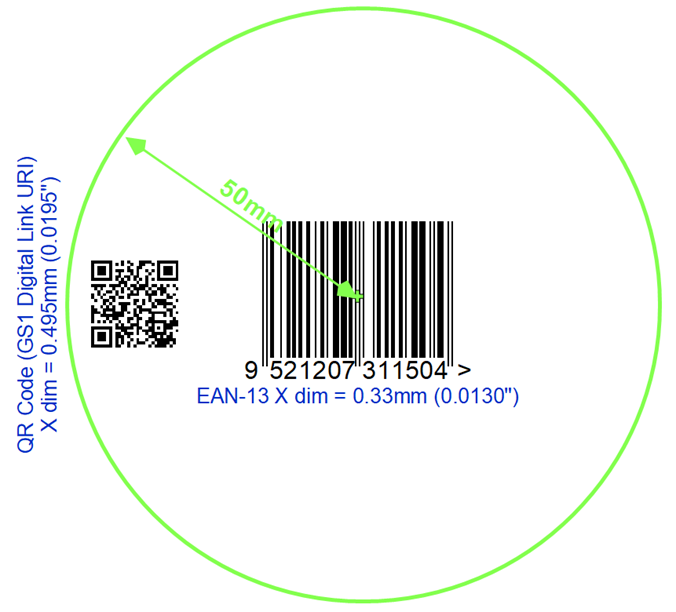

Extensive, independent testing showed that the 2D barcode needs to be within 50 mm (1.97 inches) of the linear barcode’s centre to achieve the target retail IPM. To learn more about barcode placement rules see section 6 of the GS1 General Specification.

Important: The human readable text, both human readable interpretation (HRI) and/or non-HRI text, placement is an integral part of the placement considerations see section 4.1.3 and the HRI rules for retail consumer trade items are detailed in section 4.15 of the GS1 General Specification.

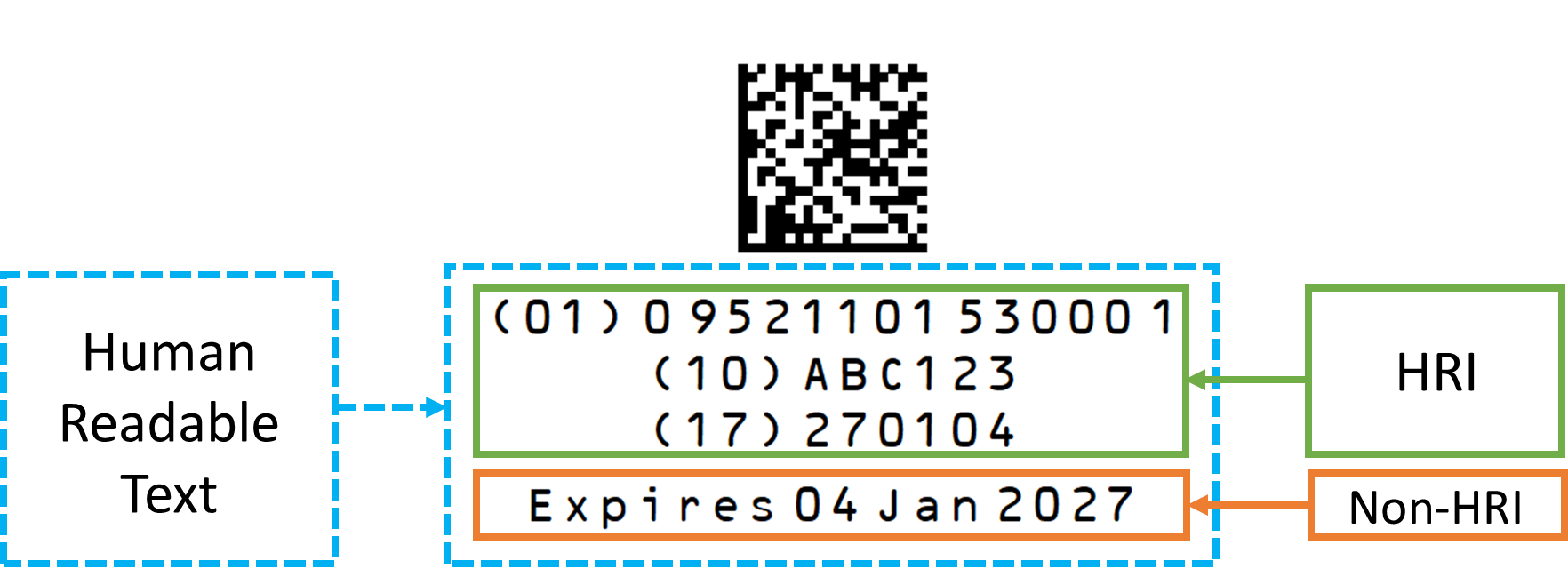

Human readable text

Human readable text is used to describe both human readable interpretation (HRI) and/or non-HRI text relating to the barcode collectively, when referencing data that is encoded into a data carrier. HRI represents the same data encoded in the barcode. Non-HRI text is all other text on the product packaging which may or may not be encoded in the barcode. If the barcode fails to scan at the retail POS, a combination of HRI and non-HRI text can be used to complete the transaction.

Human readable text requirements are dependent primarily on the following factors:

- Type and purpose of barcode

- Adjacency of the multiple barcodes

- Presence of existing HRI

- If the 2D barcode and encoded data are intended for retail POS, consumer engagement applications or internal use only

For example, in Figure 4-5, both QR Codes are identical, with the exact same GS1 Digital Link URI syntax encoded. The QR Code on the front panel does not require HRI as the brand owner intends the 2D barcode to be used for online consumer information. The QR Code on the back panel also does not require HRI as it is adjacent to an EAN-13 that has the HRI.

| Front panel | Back panel |

|

|

| Consumer engagement barcode | Adjacent POS barcodes |

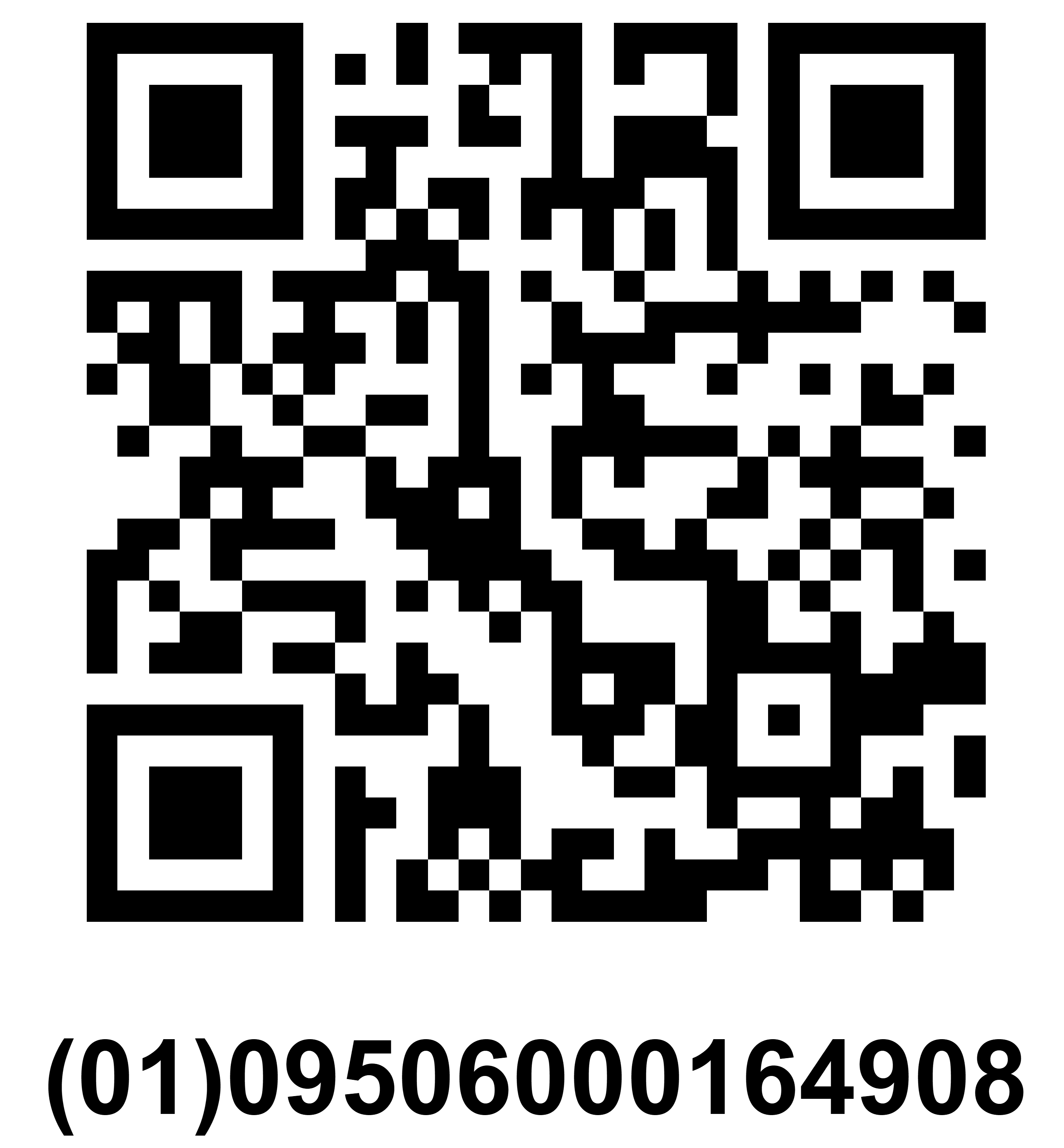

When the 2D barcode is the only barcode on the object, the 14-digit GTIN HRI will be required, as seen in Figure 4-6.

| GS1 DataMatrix (GS1 element string syntax) |

QR Code (GS1 Digital Link URI syntax) |

|

|

The HRI rules for retail consumer trade items are detailed in section 4.15 of the GS1 General Specification and include examples of multiple barcodes on the same object. Section 5.6 of this guideline provides additional examples of barcode placement and human readable text.

Choosing the right barcode

Determining which 2D barcode is best to use is dependent on what use cases need to be enabled and a variety of other factors.

To move forward, communication between all impacted stakeholders, including stakeholders internal to each organisation, is essential to ensure solutions are interoperable. For next steps, GS1 recommends considering how to ensure the path forward is collaborative and the solutions are capable and compliant. Consider the following when determining what barcode to move forward with:

Is the barcode capable of being produced and used where intended?

- Is the barcode capable of encoding a GS1 barcode syntax (i.e., plain, GS1 element strings, GS1 Digital Link URI) and approved for use on retail trade items?

- Can the barcode be created and/or applied at the speed and quality required for the use case?

- Are those intended to interact with the barcode able to process it consistently (e.g. are the back office/receiving systems ready for additional data)?

- Are barcodes produced to be conformant to the GS1 General Specifications?

Is the barcode compliant with requirements?

- Is there a regulatory requirement?

- Is there a liability disclosure requirement to the consumer and/or trading partner?

- Is the barcode approved for use in the GS1 standards for open global use via an application standard and meets all GS1 policy requirements?

- Does your industry have an agreement to use a specific type of 2D barcode (e.g., healthcare and GS1 DataMatrix)?

Note: For details on the use of GS1 DataMatrix for regulated healthcare products, see the GS1 DataMatrix Position Paper. A full list of global GS1 healthcare position papers can be found at https://www.gs1.org/industries/healthcare/position-papers.

Has the barcode decision process been collaborative?

- Have all internal and external stakeholders been brought together to enable the transition to the future solution? Such stakeholders may include:

- Industry/trading partners

- Solution partners (label designer, printing, scanning, data storing, data processing)

- Local GS1 Member Organisation

- Have the stakeholders considered the data, data carrier, packaging, scanning hardware/software, and receiving systems' needs and existing capabilities?

Each section of this document encapsulates these guiding principles, including detailing the stakeholder for collaboration, referencing solution capabilities and compliance.

For more information see the GS1 2D in retail barcodes explorer.

Overview 2D barcode considerations

Throughout this guideline, additional details will be given to support determining which 2D barcode will be best suited for different scenarios. The following is a high-level summary of key points and is not an exhaustive list.

Important: Much like transitioning from linear to 2D barcodes, it is possible to change between 2D barcode types and change the type of data included in the barcode as use cases evolve. While it may be ideal to only change the barcode being used once, it can change more over time based on use case needs. Once updated, retailer systems will be able to read GS1 DataMatrix with GS1 element string syntax and QR Code with GS1 Digital Link URI syntax and Data Matrix with GS1 Digital Link URI syntax.

GTIN explanation

A Global Trade Item Number (GTIN), is the GS1 standard for unique identification of products and services, known as trade items. The GTIN is globally used in barcodes to enable the accurate identification of items throughout supply chains and in post-purchase activities.

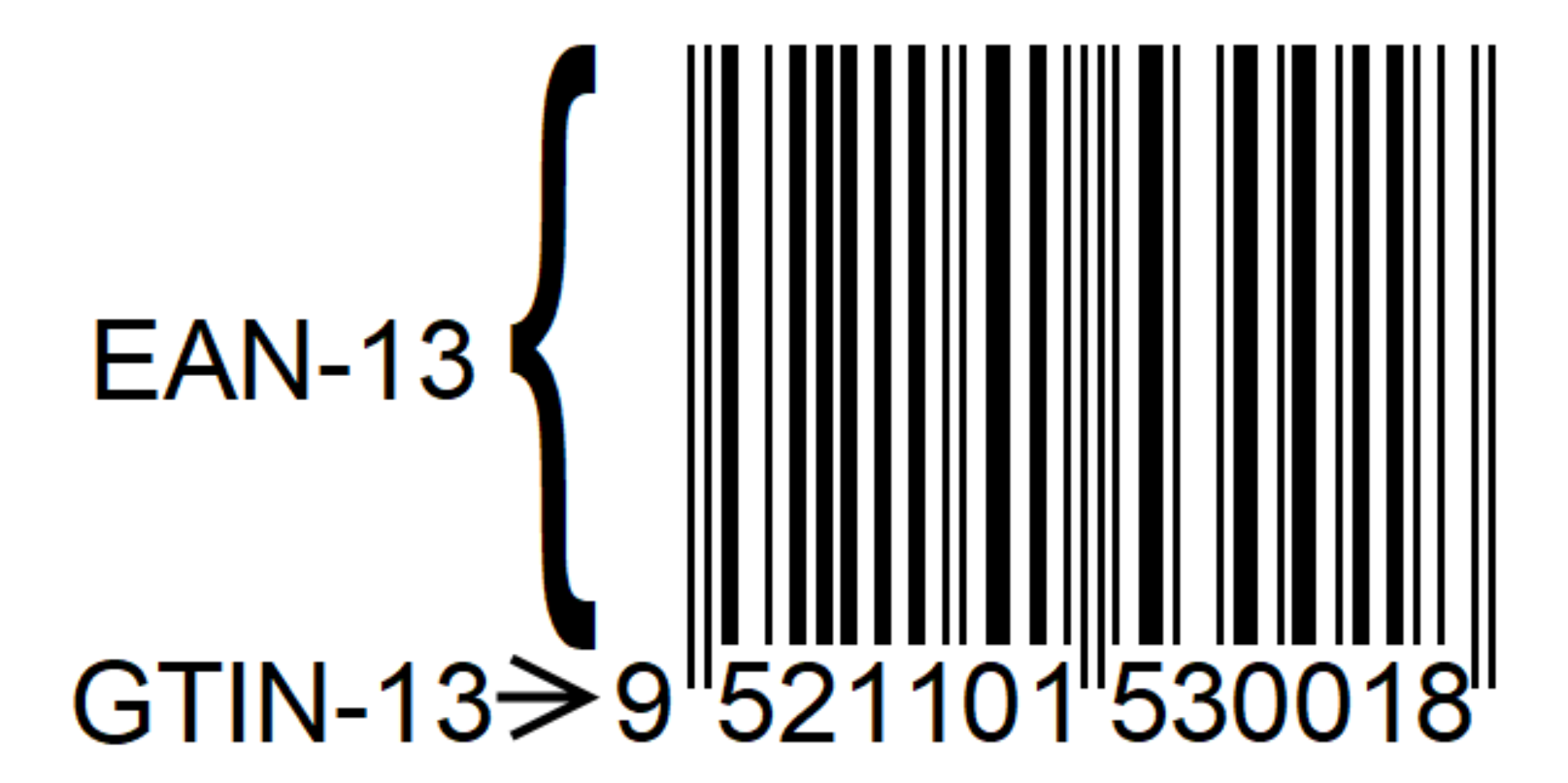

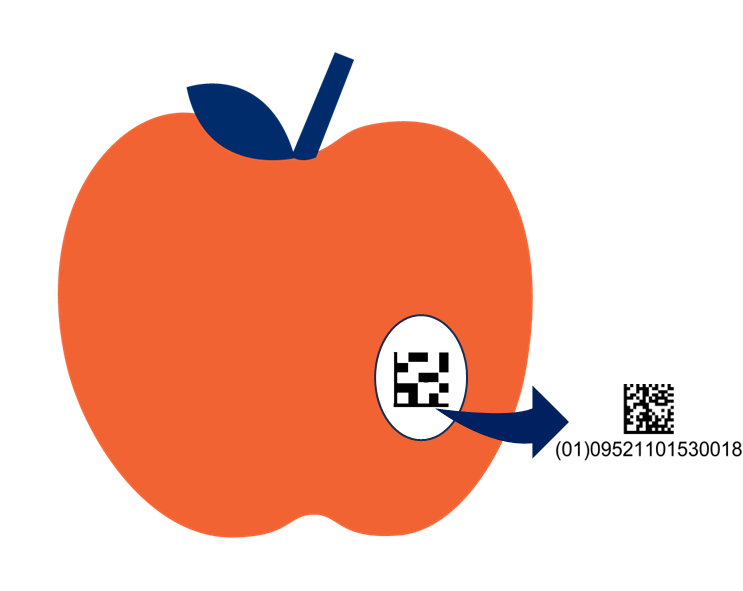

GTINs are widely used in various industries, such as retail, healthcare, manufacturing, logistics and e-commerce, to uniquely identify products and facilitate efficient inventory management and product tracking. In retail, GTIN can be encoded in different barcode symbologies, including UPC (Universal Product Code), EAN (European Article Number), GS1 DataBar retail POS family, GS1 DataMatrix, Data Matrix with GS1 Digital Link URI syntax and QR Code with GS1 Digital Link URI syntax.

During the dual-marking transition phase, the trade item will feature both the current EAN/UPC barcode and either a GS1 DataMatrix or QR Code with GS1 Digital Link URI syntax or a Data Matrix with GS1 Digital Link URI syntax.

Note: Book, serial publications and music numbering systems use the International Standard Book Number (ISBN), International Standard Serial Number (ISSN) and International Standard Music Numbers (ISMN) system, respectively, which are compatible with GTIN-13 and can be encoded in EAN/UPC family of barcodes.

Which GTIN can be used and the structure of that GTIN varies based on the barcode symbology. For example, a GTIN-13 is encoded into the EAN-13, while GTIN-12 is encoded in the UPC-A. For more guidance on GTINs, see the GS1 General Specifications and GTIN Management Standard.

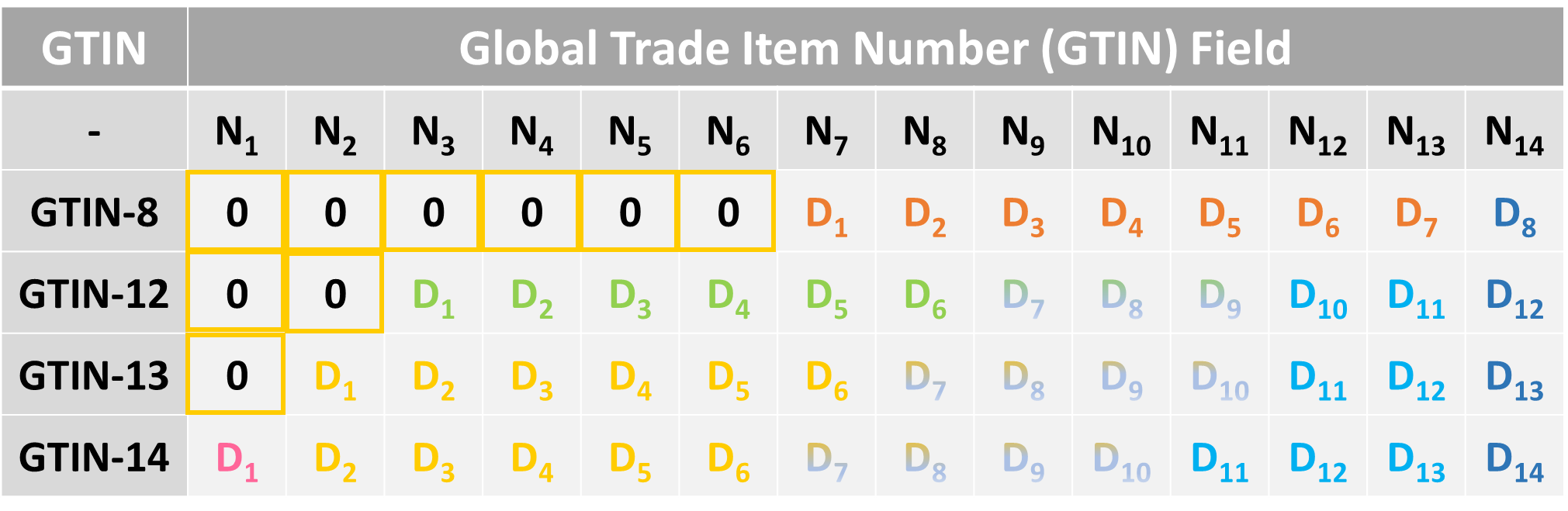

GS1 DataBar retail POS family, GS1 DataMatrix, QR Code with Digital Link URI syntax and Data Matrix with GS1 Digital Link URI syntax use the zero padded, 14-digit format of GTIN-13, GTIN-12 and GTIN-8. When any of these GTINs are encoded in a data carrier that must encode a fixed-length data string of 14-digits, the GTINs less than 14 digits must be prefixed by leading zeroes that act as filler digits, see Figure 4-8.

Important: All retail systems interacting with GTINs must be able to interact with GTIN-13, GTIN-12 and GTIN-8. For more information, contact your local GS1 Member Organisation.

- ‘N’ represents the digit placement in an application, database or barcode that require a 14-digit format.

- ‘D’ represents the digit allocated for each position of the GTIN.

- The GTIN-13, GTIN-12 and GTIN-8 structures are right-justified and zero padded with leading zeroes ‘0’ serving as filler digits to complete the required 14-digit format.

Important: GTIN-14 cannot be used to identify trade items sold at retail POS and are not in scope for this implementation guideline. For more guidance on GTIN-14 and its uses, see the GS1 General Specifications and GTIN Management Standard.

(*) See GS1 General Specifications for application and GTIN rules for retail

Barcode data beyond GTIN

The GTIN uniquely identifies a trade item by serving as its means of primary identification. Sometimes, there is a need to provide additional information beyond the GTIN. Using data beyond the GTIN provides more granular and detailed information about a product and can include data elements such as batch/lot number, serial number and expiration date. GS1 element string and GS1 Digital Link URI are the two GS1 barcode syntaxes that enable the use of additional data in barcodes, see section 4.5 for more information on syntaxes. Depending on the needs of each use case, the additional data may need to be scanned, processed, stored and used in the POS system. To use the additional data, systems may need to be upgraded. The implications for both hardware and software will be explored in this guideline.

Benefits of implementing GTIN with additional barcode data

Consumers are demanding access to more information both online and on product labels and they expect retailers and regulators to protect them from purchasing expired, counterfeit, or unsafe products.

Along with these consumer needs, retailers and suppliers also benefit from increased supply chain visibility, enhanced recall readiness abilities and improved sales data.

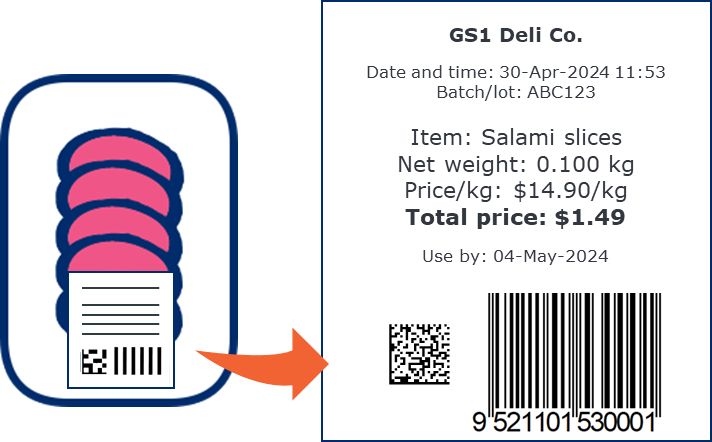

Encoding additional data to support the GTIN in the barcode can make this possible, as it enables automation and validation information throughout the supply chain and at the point-of-sale (POS). This data can, for example, include weight, best before date, lot/batch number and serial number. Further details on additional data options and their implications for printing, scanning and utilisation are elaborated upon in sections 5, 6, and 7.

Implementing GTIN with additional data about the item can support the following business use cases and more:

- Consumer and food safety programs at the register and on the consumer receipt

- Improved quality control of products on the shelf

- Food waste prevention/management

- Expiration date management. For example, by encoding the product’s expiry date, it becomes possible to automatically prevent the sale of out-of-date products at the POS

- Global or regional traceability initiatives and more effective targeted recalls

- Category/promotional management

- Inventory replenishment and reduced out of stocks

- Returns management

- Improved pricing accuracy at POS (e.g., automatic price mark-downs based on date)

- Global or regional regulatory compliance

- Product authentication and anti-counterfeit

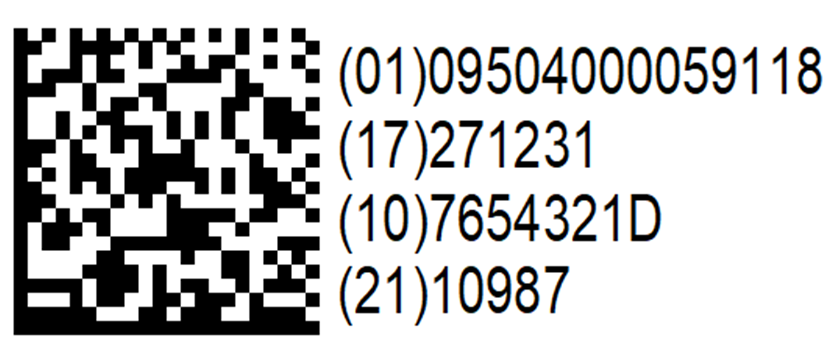

GS1 Application Identifiers

A GS1 Application Identifier (AI) is a numeric code of two or more digits that uniquely defines the format and meaning of the information that follows the AI. AIs enable several pieces of data to be encoded in one barcode and so the information can be interpreted and processed correctly and consistently. GS1 element string or GS1 Digital Link URI syntaxes enable the use of GTIN and additional data in barcodes. Which AIs to use will be determined based on the targeted use case.

Note: Not all GS1 Application Identifiers will be enabled across all retailers. Which AIs are available and able to be used can vary based on where it is being read.

Important: To aid readability within the body text of this guideline, AIs are displayed in round brackets following their text description, e.g., serial number (21).

Table 4-3 contains the AIs that are often used to support retail applications.

* Technical details about format and separator character requirements can be found in the GS1 General Specifications

** If only year and month are available, DD must be filled with two zeroes. As of 1 January 2025, all regulated healthcare products using the GS1 Application Identifiers for expiration date or production date in their barcode require a valid day of the month (i.e., 01-31).

*** The fourth digit of this GS1 Application Identifier indicates the implied decimal point position. Example: 3103 Net weight in kilograms with three decimal points

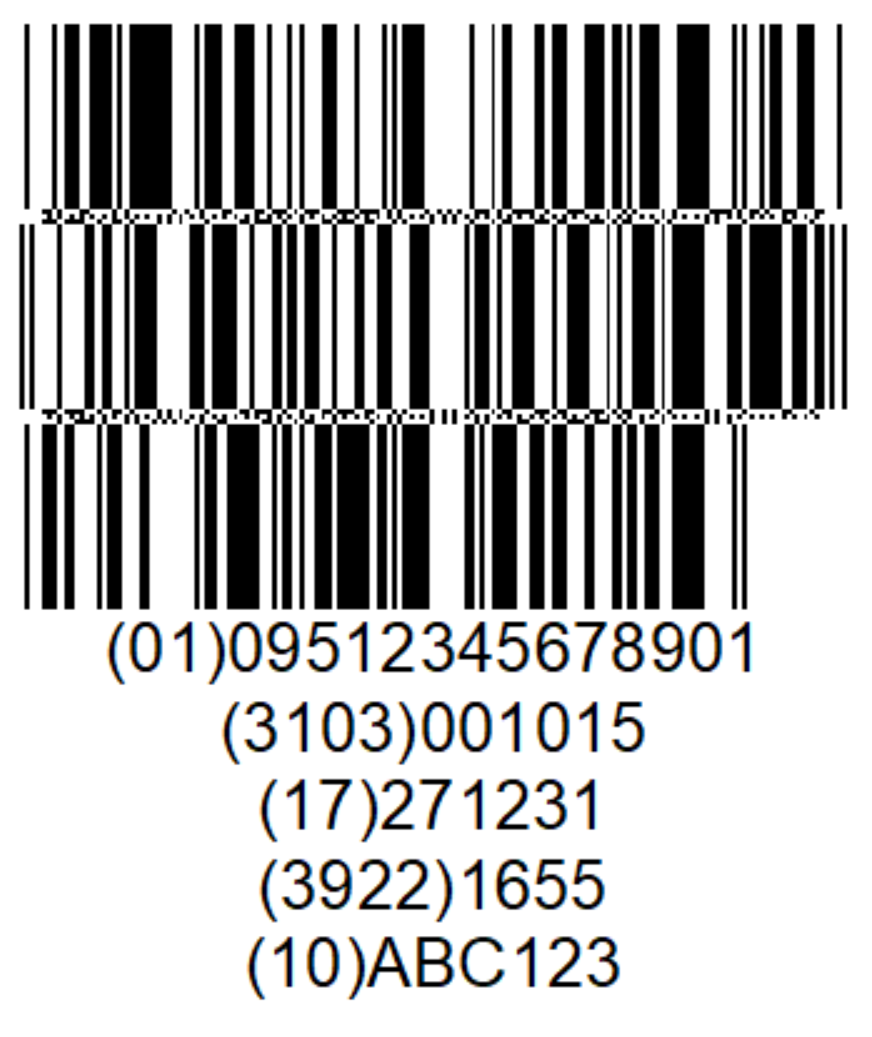

Figure 4-10 shows how data could be structured using GS1 element string syntax for variable measure trade items sold at POS. The same data is encoded in the GS1 DataBar Expanded Stacked and the GS1 DataMatrix, for illustrative purposes.

- (01) Global Trade Item Number - 09512345678901

- (3103) Net weight, kg - 1.015 kg

- (17) Expiration date - 31 December 2027

- (3922) Price to pay - $16.55

- (10) Batch or lot number - ABC123

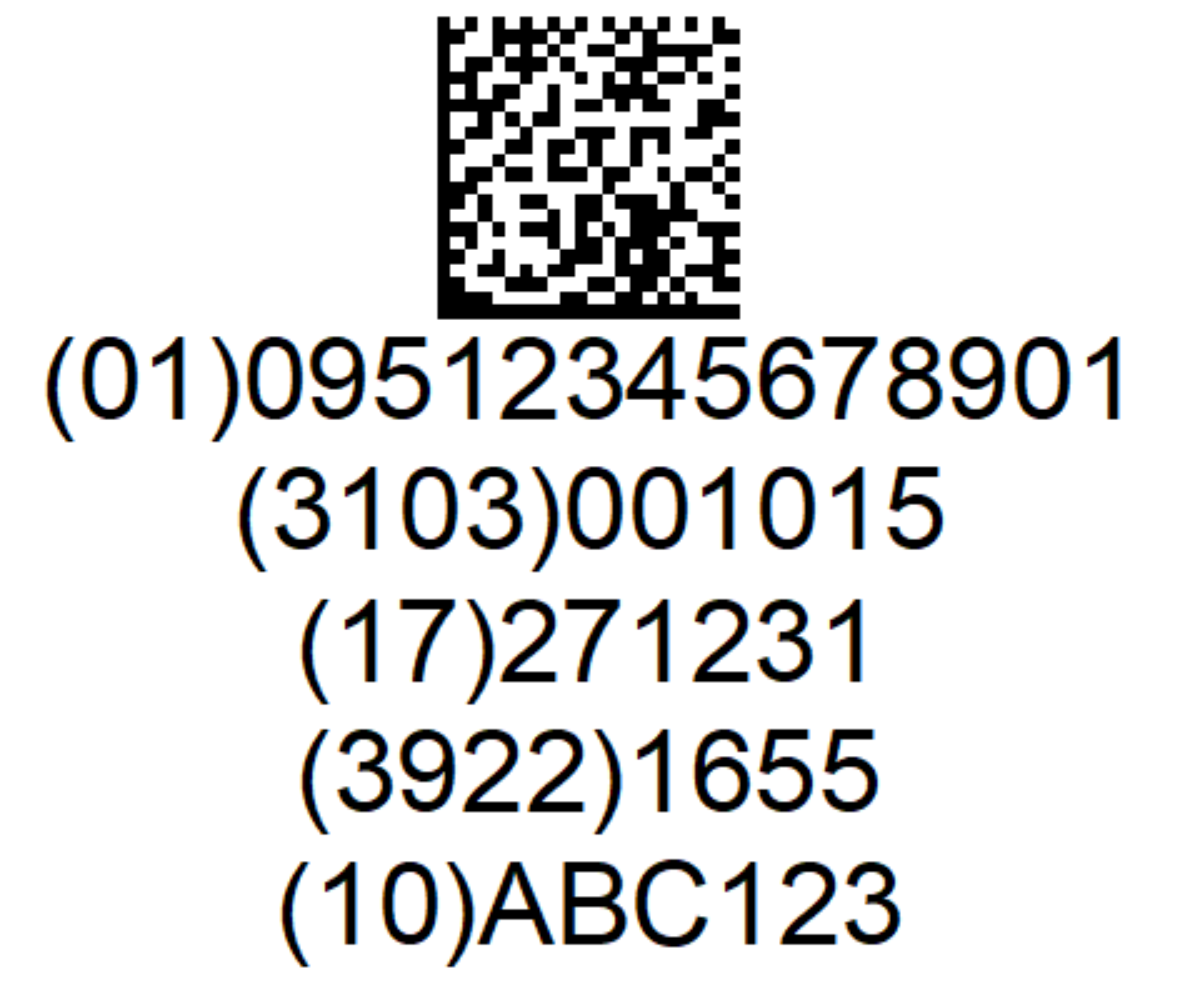

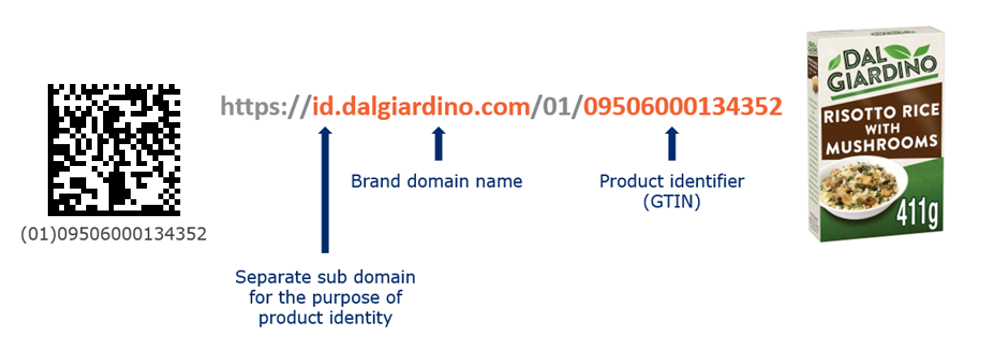

Figure 4-10 shows how data could be structured using GS1 Digital Link URI syntax for fixed measure trade items sold at POS. The data is encoded in a QR Code with GS1 Digital Link URI syntax, for illustrative purposes.

https://example.com/01/09506000134352/22/73/10/ABC?11=230718

See section 4.5 for an overview of GS1 barcode syntaxes, including the GS1 Digital Link URI syntax.

- (01) Global Trade Item Number - 09506000134352

- (22) Consumer product variant - 73

- (10) Batch or lot number - ABC

- (11) Production date - 18 July 2023

Sharing of other types of data

The core reason to use any data carrier, 2D barcodes included, is to identify a physical object and key details about it as it moves through its lifecycle and connect it with digital information. In the case of products, the unique Global Trade Item Number (GTIN) is used to tie together the physical and digital information. When coupled with additional identification elements, like consumer product variant, batch/lot number and/or serial number, more exact, detailed information can become available.

The digital information tied to a GTIN is initiated long before the physical product is produced and will remain long after the product’s lifecycle ends. This digital information addresses needs beyond what barcodes can do alone. If looking to share information beyond what is in the barcode or linked to via the barcode, refer to additional GS1 standards and guidelines.

- Product data sharing

2D barcodes are an enabler to access and unlock further data and data sharing related standards and services, such as:

- GS1 Global Data Model (GDM): The GDM clarifies data requirements across trading partners by defining the attributes needed to list and sell a product in a given market.

- GS1 Global Data Synchronisation Network (GDSN): The GDSN is the world’s largest product data network. Here, standardised product content is uploaded, maintained and shared automatically, ensuring trading partners have immediate access to the most current and complete information needed to exchange products on both local and global markets.

- Verified by GS1: With the Verified by GS1 service, users can verify the identity and ownership of any GS1 identifier, product, company and location, based on basic data provided by the data owner that can be accessed openly and globally.

- GS1 Web Vocabulary: The GS1 Web Vocabulary makes it easier to include detailed structured data about a product for a web page using a standard vocabulary. The structured data about the product can then be used by search engines, mobile device apps, etc. to deliver a richer experience to the consumer.

- Transactional data sharing with GS1 Electronic Data Interchange (EDI): EDI provides global standards for electronic business messaging that allow automation of business transactions commonly occurring across the entire supply chain. Users in North America use the X-12 standard for EDI and can contact their local MO to learn about EDI requirements in their region

- Visibility data sharing with Electronic Product Code Information Services (EPCIS): EPCIS is a data sharing standard for enabling visibility, within organisations as well as across an entire supply chain of trading partners and other stakeholders. It helps provide the “what, when, where, why and how” of products and other assets, enabling the capture and sharing of interoperable information about status, location, movement and chain of custody.

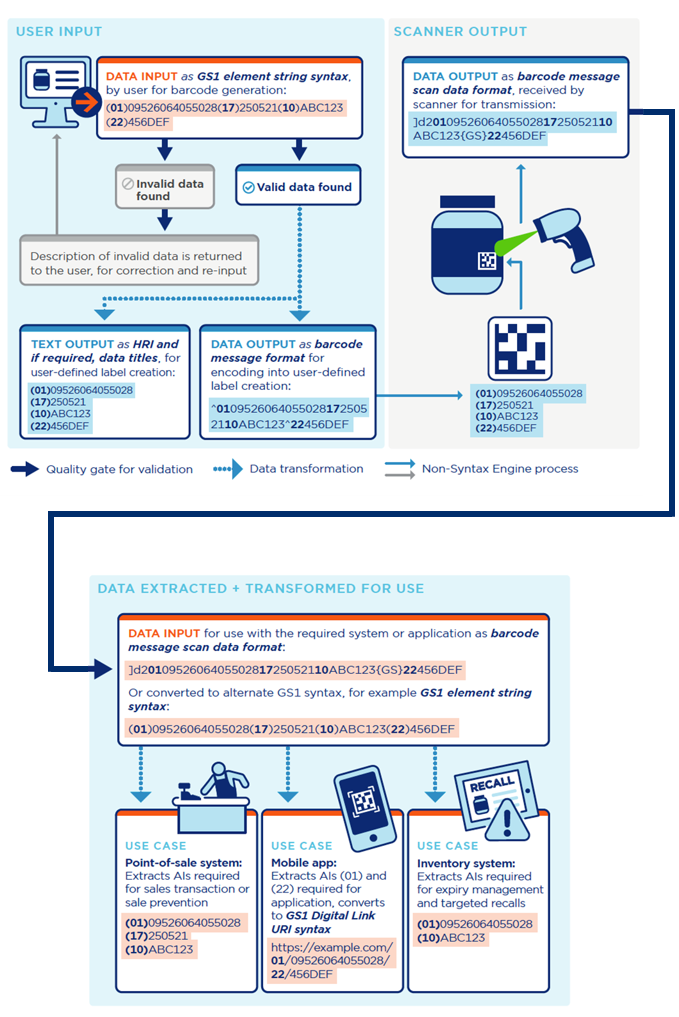

GS1 barcode syntaxes used in retail POS

GS1 has three syntaxes suitable for encoding in barcodes scanned at retail point-of-sale (POS):

- Plain syntax: GS1 data structure containing a GS1 identification key with no additional characters or syntactic features. This format is used for EAN/UPC family barcodes, where only a GTIN is to be encoded, without any GS1 Application Identifiers (AIs) or any other data. For example, a GTIN-13 appears in plain syntax as 9526064055028.

- GS1 element string syntax: a syntax for expressing GS1 identification keys and other data using GS1 Application Identifiers (AIs). In the human readable text associated with the barcode, AIs are surrounded by parentheses to aid readability and support input or display within user interfaces (e.g., barcode generator software). Parentheses are never encoded directly to the barcode. For information on how the human readable text associated to the barcode is displayed, see section 4.1.3.

For example, not including non-keyboard characters like FNC1, a GTIN, expiration date, batch/lot number and serial number, using GS1 element string syntax, would be encoded into the barcode as 01095260640550281725052110ABC12321345DEF.

- GS1 Digital Link URI syntax: a web URI syntax for expressing GS1 identification keys and other data in a format using GS1 Application Identifiers (AIs) as specified in the GS1 Digital Link URI standard. GS1 Digital link URI incorporates elements of existing web standards, such as domain name, that allow the barcode to connect users to the web. For example, a domain name, a GTIN, expiration date, batch/lot number and serial number using GS1 Digital Link URI syntax would be encoded into the barcode as: https://example.com/01/09526064055028/10/ABC123/21/345DEF?17=250521. For information on how the human readable text associated to the barcode is displayed, see section 4.1.3.

The figure below provides a summary of the barcode and syntax options that can be used at retail POS as outlined above, noting where data beyond GTIN is supported in the GTIN attribute column and which device types can support decoding.

For further information on GS1 standards, see section 7.2.2 for barcode encoded data structures (syntaxes), Best practices for creating your QR Code powered by GS1, GS1 General Specifications and GS1 Digital Link URI Standard.

Using GS1 element string syntax

The GS1 element string syntax is widely used throughout the supply chain and supports the ability to provide important data where it is needed in healthcare, food, logistics units and a host of other locations. The majority of barcode creation and scanning solutions on the market already have the capability to encode and decode GS1 element strings used with linear barcodes such as the GS1 DataBar family and GS1-128, as well as the GS1 DataMatrix which is a retail POS compliant 2D barcode.

The GS1 element string syntax requires an understanding of GS1 Application Identifiers (AI) and their conformance requirements, as listed below. Once the required data is structured correctly as a GS1 element string, it is simpler to convert to a GS1 Digital Link URI for encoding into a 2D barcode. Please see section 7.2.3 for information on the GS1 Barcode Syntax Resource and enabling capability for encoding solutions.

Key considerations for element string syntax:

- Selecting the correct GS1 AI to represent the encoded data, for example:

- USE BY OR EXPIRY (17) vs BEST BEFORE or BEST BY (15)

- ORIGIN (422) vs COUNTRY - PROCESS (424)

- Data format

- Data length, fixed or variable

- Character sets e.g., numeric, alphanumeric, or restricted character set

- Data components or segments e.g., check digits/characters, indicator digits or characters, ISO code lists, piece number and total count etc.

- Whether a Function 1 symbol character (FNC1) is required as a separator character

- Most AIs require a FNC1 to indicate the end of the AI data field and the start of the next AI. These are defined by GS1 standards as “non-predefined length” AIs, whereas the AIs that do not require FNC1 are defined as “predefined length” AIs. For information on “predefined length” AIs see section 7.8.5 of GS1 General Specifications.

- Data relationships

- Mandatory pairs of AIs e.g., if serial number (21) is encoded, it must be encoded with GTIN to be meaningful

- Invalid pairs of AIs e.g., if country of origin (422) is encoded, it cannot be encoded with country of full processing (426) as it can lead to ambiguous data

- For details on data relationship requirements, see section 4.13 of the GS1 General Specifications.

Benefits of using GS1 element string syntax in 2D barcodes

The GS1 element string syntax in a GS1 DataMatrix barcode provides several benefits, contributing to efficient and standardized data encoding for identification purposes in the supply chain ecosystem.

- Efficient use of space: GS1 DataMatrix barcodes aim to encode a significant amount of information in a relatively small space. The structured GS1 element string syntax optimises data representation, allowing for efficient use of the barcode's capacity.

- Enhanced data integrity: GS1 element strings promote data integrity through the inclusion of check digits and other validation mechanisms ensuring that the encoded data is accurate and can be reliably interpreted.

- Compliance with regulatory requirements: Many industries, including healthcare and regulatory bodies, mandate the use of GS1 standards for product identification and traceability. GS1 element strings in GS1 DataMatrix barcodes help organisations comply with these requirements.

- Traceability: GS1 element strings enable the inclusion of unique identifiers, such as GTINs (Global Trade Item Numbers) or Serial Shipping Container Codes (SSCCs), ensuring each item is uniquely identified within the supply chain. Including Application Identifiers (AIs) for batch or lot numbers in the GS1 element string allows for traceability of products back to specific production batches, aiding in quality control and recall management. The use of AIs for serial numbers facilitates traceability at the individual item level. This is crucial for tracking and monitoring the movement of each unique product throughout its lifecycle.

- Ease of set-up: For those that do not require web connectivity, use of GS1 element string syntax can provide a smaller barcode than linear barcodes and more data without the additional set-up required to connect a GS1 Digital Link URI barcode to the web.

- Existing GS1 element string syntax use: GS1 element string syntax has been in use far longer than GS1 Digital Link URI. Barcodes like GS1 DataBar expanded and GS1-128 use the same data format as GS1 DataMatrix. As a result, it is more likely to be in systems than GS1 Digital Link URI. Scanners and backend systems are more likely to read and decipher the information in this syntax.

- Focus on AI data structure only: GS1 element string syntax may act as a transition phase between plain syntax to GS1 Digital Link URI syntax, as it only requires an understanding of GS1 Application Identifiers (AI) and their conformance requirements. This means there is no need to understand key-qualifier versus parameters, or URI reserved characters etc.

Using GS1 Digital Link URI syntax

The GS1 Digital Link URI syntax can fulfil the exact same business processes that are fulfilled by a GS1 element string syntax today and well into the future (provided that the capability to recognise, use or convert a GS1 Digital Link URI has been enabled). However, a GS1 Digital Link URI has the added benefit of behaving like a Web URL to provide digital content about the data encoded in the 2D barcode. It can also provide different types of digital content to different users. See Connecting barcodes to related information for more information on this topic.

For example, consider a GS1 Digital Link URI with GTIN and batch/lot number, encoded in a QR Code or Data Matrix on a pack of steaks. When a consumer scans the 2D barcode with their mobile device’s camera without any app, detailed traceability information about that specific batch of steaks can be provided, with web content possibly showing where the cow may have been born, raised, slaughtered and processed. Whereas for retail staff, the same 2D barcode can be scanned with a specialised app to retrieve traceability information about that specific batch of steaks, but this information is provided as structured master data which can be used for other business purposes, including those which may need to be automated or machine-readable.

Implementing or enabling capability to use a GS1 Digital Link URI requires knowledge of the syntax structure, subdomains and back-end coordination, when compared to GS1 element strings. See Best practices for creating your QR Code powered by GS1 and the video about Why QR Codes powered by GS1 are more than a marketing tool.

Important: It is important that a GS1 Digital Link URI is not used as the address of a web page. Rather, it is recommended to redirect to digital information about the identified product. There are two reasons for this. First, a GS1 Digital Link URI identifies the product itself, not the digital information about the product. Secondly, GTINs are allocated and managed according to the GS1 Allocation Rules whereas digital content, especially marketing-driven websites, are managed by brand marketing teams who will follow different procedures with different priorities. For more on this topic see Best practices for creating your QR Code powered by GS1.

Benefits of using GS1 Digital Link URI syntax in 2D barcodes

Using GS1 Digital Link URI syntax creates 2D barcodes that are multifunctional, meaning they can connect consumers to the brand’s website of choice, while also containing valuable information that simultaneously powers point-of-sale (POS) and many other business processes. Examples of advantages that contribute to a more transparent, engaging and efficient retail experience for businesses and consumers alike include:

- Improved consumer engagement: GS1 Digital Link URI syntax enables interactive experiences and enhanced consumer engagement. By scanning the barcode, consumers can be directed to websites, or other digital content related to the product or brand. This opens up opportunities for personalised marketing, loyalty programs, product tutorials, digital patient leaflets for pharmaceutical products, digital instructions for using medical devices, customer reviews and other interactive experiences that deepen the connection between consumers and brands.

- Enhanced product information: GS1 Digital Link URI syntax expands the capabilities of general use barcodes such as Data Matrix and QR Code, by enabling the inclusion of GS1 Identification with web links. Businesses can use this as access to additional product information, such as ingredient details, allergen information, sustainability data, product certifications and more. Consumers can access this information by scanning the barcode with a mobile device, enhancing transparency and enabling informed purchasing decisions.

- Traceability and transparency: GS1 Digital Link URI syntax can be used to embed additional data, such as batch/lot number or serial number, which enables consumers and businesses to access online traceability information, associated with the GTIN and batch/lot or serial number. This creates opportunities for businesses to provide real-time supply chain visibility to consumers. For instance, consumers can trace the origin of a product, view production or harvest dates, learn about quality control measures and understand the environmental impact of the product's lifecycle. This transparency can help build consumer trust and support sustainable and ethical purchasing decisions.

- Simplified mobile commerce: GS1 Digital Link URI syntax enables seamless integration between physical products and online commerce platforms. By scanning the barcode, consumers can access e-commerce websites, product catalogues, or online marketplaces directly from their mobile devices. This simplifies the purchasing process, enabling consumers to explore additional product variations, check prices, read reviews and make convenient online purchases.

- Flexibility and future-proofing: GS1 Digital Link URI syntax is designed to be flexible and adaptable to evolving technology trends. It supports various barcode formats, including QR Code and Data Matrix. This flexibility helps ensure compatibility with different scanning devices and software applications, allowing businesses to future-proof their barcode implementation.

Optimising the 2D barcode size and data

Optimising the size and data encoded in a GS1 DataMatrix, Data Matrix or QR Code can improve scanning performance as 2D barcodes with an overall smaller size are generally, faster to scan and take up less space on-pack. It is expected that all barcodes are produced in compliance with the GS1 General Specifications and relevant ISO/IEC standards.

Important: The size referenced is the overall size of the barcode and not the size of the barcode’s X-dimension. X-dimension that goes below the allowed sizes in the GS1 General Specifications Symbol Specification Tables are more difficult to scan than larger X-dimension sizes.

When the 2D barcode is compact, it reduces the time required for a scanning device to capture and interpret the information as the 2D barcode is completely in view of the scanner faster. When printing GS1 DataMatrix, Data Matrix or QR Codes on small trade items, or on curved surfaces the size becomes a critical factor. Smaller 2D barcodes are more effective for printing on garment tags, labels, or packaging, and they are also more suitable for display on mobile screens. In addition, small efficiently encoded 2D barcodes can reduce the amount of data that needs to be transferred over a network and ease the printing of dynamic data (e.g., serial numbers) based barcodes. There are several other advantages to having a 2D barcode size that is optimised, such as:

- Transition period: During the 2D migration transition period both linear and 2D barcodes will need to coexist, so optimising the 2D barcode size helps ensure brand marketing and packaging designers still have sufficient space for their purposes.

- Readability and reliability: An optimised 2D barcode is more likely to be readable under various conditions. This includes scenarios with poor lighting, low-resolution cameras, or when the code is partially obscured or if the surface is not flat. Optimising size and data encoding helps improve the reliability of scanning.

- Mobile app performance: Mobile devices, especially older models or those with limited processing power, may struggle with decoding large or complex 2D barcodes. Optimising size and data encoding can improve performance on a wide range of devices.

- Aesthetic considerations: In applications where 2D barcodes are part of a design, such as marketing materials or product packaging, a smaller, well-optimised code can be more aesthetically pleasing and less obtrusive.

In summary, optimising the size and data encoded in 2D barcodes is crucial for improving scanning performance, ensuring readability, enhancing user experience, and addressing practical considerations related to printing, display and data capacity. Optimising the encoding of a 2D barcode involves adjusting various parameters to ensure that the 2D barcode is efficient, readable and reliable. Sections in 4.6.1 below provides an overview of the various parameters that can affect the size of 2D barcodes. Note that the size of the 2D barcode will be determined by the specific symbology selected along with these parameters.

For more information, see the following references:

- Best practices for creating your QR Code powered by GS1:

https://ref.gs1.org/docs/2023/QR-Code_powered-by-GS1-best-practices - Connecting barcodes to related information:

https://ref.gs1.org/docs/2024/connecting-barcodes-to-related-information - GS1 Digital Link quick start guide:

https://ref.gs1.org/docs/2024/digital-link-quick-start-guide - GS1 DataMatrix Guideline:

https://www.gs1.org/docs/barcodes/GS1_DataMatrix_Guideline.pdf - Video about “Why QR Codes powered by GS1 are more than a marketing tool”

https://youtu.be/2VFsVfYd6Z0

Data and format considerations

The format of data encoded in a 2D barcode, as well as the type of data included, can also have an impact on the physical size of the barcode produced. It is important to be mindful of the following considerations.

- Variable length data

- When using variable length GS1 Application Identifiers (AIs), the available capacity does not necessarily need to be filled to its maximum, as more data can result in a larger barcode.

- For example, the amount payable for a variable measure trade item (392n) allows up to 15 characters, however a 6-character amount with the decimal point indicator can be sufficient for most use cases.

- Another example is the serial number (21), which allows up to 20 characters, however a 10-character serial number can be sufficient as it must be used with a GTIN to uniquely identify a specific trade item instance.

Note: The same 10-character serial number can be used repeatedly with different GTINs, as it is the combination of the GTIN and serial number that provides unique identification of the trade item.

- Characters

- Some AIs allow alphanumeric characters that include digits, lowercase and uppercase alpha characters, and special characters such as “-”, “/”, “#” etc.

- □ Different types of characters require different amounts of data capacity when encoded, and switching between character types, including when percent-encoding is required, can also require more data capacity when switching between encoding modes.

- The choice of characters within a data string can impact the size of the barcode produced:

- Digits use the least amount of data capacity when compared to alpha or special characters.

- Uppercase characters use less data capacity when compared to lowercase or special characters.

- Changing between character types requires more data capacity than when using a single character type.

- Encoded data:

https://example.com/01/09526064055028/22/TEST/10/ABC123/21/435DER?17=250521 versus

https://example.com/01/09526064055028/22/test/10/abc123/21/435der?17=250521

For technical details on the use of GS1 Digital Link URI structures, including percent encodings and optimisation in QR Codes, see section 7.2.2.

- Sequence of predefined versus non-predefined length data for GS1 element string only

- The sequence of predefined and non-predefined length AIs can have some impact on the size of a barcode, although it’s worth noting that the impact is minimal, when compared to the previous points.

- When encoding a GS1 element string, all “non-predefined length” AIs except for the last data element in the string, require the Function 1 symbol character (FNC1) to be used as a separator character.

- Switching between encoding modes to encode a FNC1 uses additional data capacity, therefore it is recommended to encode the predefined length AIs before any non-predefined length AIs where possible.

- More information can be found in the GS1 General Specifications, section 7.8 Processing of data from a GS1 symbology using GS1 Application Identifiers.

- Minimum data set for encoding

- The amount of data encoded in a 2D barcode can directly impact the physical size of the 2D barcode produced, and adding more data into the barcode can increase complexity to create it.

- Not all data needs to go into a barcode to be useful. Only data that is essential to be automatically captured and acted upon goes into a barcode. Other data can be associated or linked to through other means.

- For example, a retailer might require Country of Origin on all cosmetic trade items to provide online traceability information to consumers, as well as for import and export requirements.

- Country of Origin for the trade item can be encoded with (422) along with GTIN (01). It will also likely be associated with the trade item’s batch/lot number (10), as each batch/lot can be produced in different locations.

- In this case, Country of Origin is not needed at POS, but is needed for general distribution and for digital content directed at consumers. So, the 2D barcode applied to the trade item only requires the GTIN (01) and batch/lot (10) to be encoded, since the Country of Origin data can be associated with the GTIN and batch/lot number, as master data for B2B requirements, and as linked data for B2C requirements.

Choose the right encoding strategy

GS1 DataMatrix, Data Matrix and QR Code support different encoding modes (e.g., numeric, alphanumeric, binary, and Kanji). The encoded barcode data is a sequence of message segments, each encoding a section of the data in a certain mode.

Careful selection of the sequence of modes that best suits the type of data in different sections of the message can minimise the size. For example:

- If the data primarily consists of consecutive run of numbers, using the numeric encoding mode for that section can result in a more compact barcode.

- If the data includes a combination of numbers and letters, the alphanumeric encoding mode might be more efficient than binary mode within that section.

In the encoded barcode message, non-data characters, or segment headers, facilitate transitions between different encoding modes. However, these mode shifts come with an encoding length cost. Therefore, frequently changing modes to represent short runs of specific data types may outweigh any potential benefits. Different encoding schemes can be employed to represent the same barcode message, each with varying levels of efficiency.

Ideally the barcode encoder (image generator) will determine the optimal sequence of mode changes that minimises the overall length of encoded messages for the given data. This strategic approach to message encoding can often lead to a reduction in the size of the barcode image. When generating a GS1 DataMatrix, Data Matrix or QR Code, the choice of encoding mode is often handled automatically by the encoding software based on the content being encoded. Most barcode generators will follow the informative optimisation procedure described by the relevant symbology standard. However, some barcode generators do not use optimisation techniques and will instead resort to a single mode for the entire message.

Users typically do not need to manually specify the encoding mode, but it can be useful to understand how the different modes work if you want to optimise QR Code generation for specific types of data. Users are advised to do their own testing with a range of available encoder toolkits to make their own assessment about which provide the most efficient encoding.

The many commercial and open-source barcode encoding software solutions include automatic encoding mode sections leading to a mixed mode 2D barcode. These mixed mode 2D barcodes are supported by scanner solutions that conform to the ISO standards for GS1 DataMatrix and Data Matrix: ISO/IEC 16022 Information technology - Automatic identification and data capture techniques - Data Matrix barcode symbology specification and QR Code: ISO/IEC 18004 Information technology - Automatic identification and data capture techniques - QR Code barcode symbology specification.

See Annex 8.3 for the details of the encoding modes used in GS1 DataMatrix, Data Matrix and QR Codes.

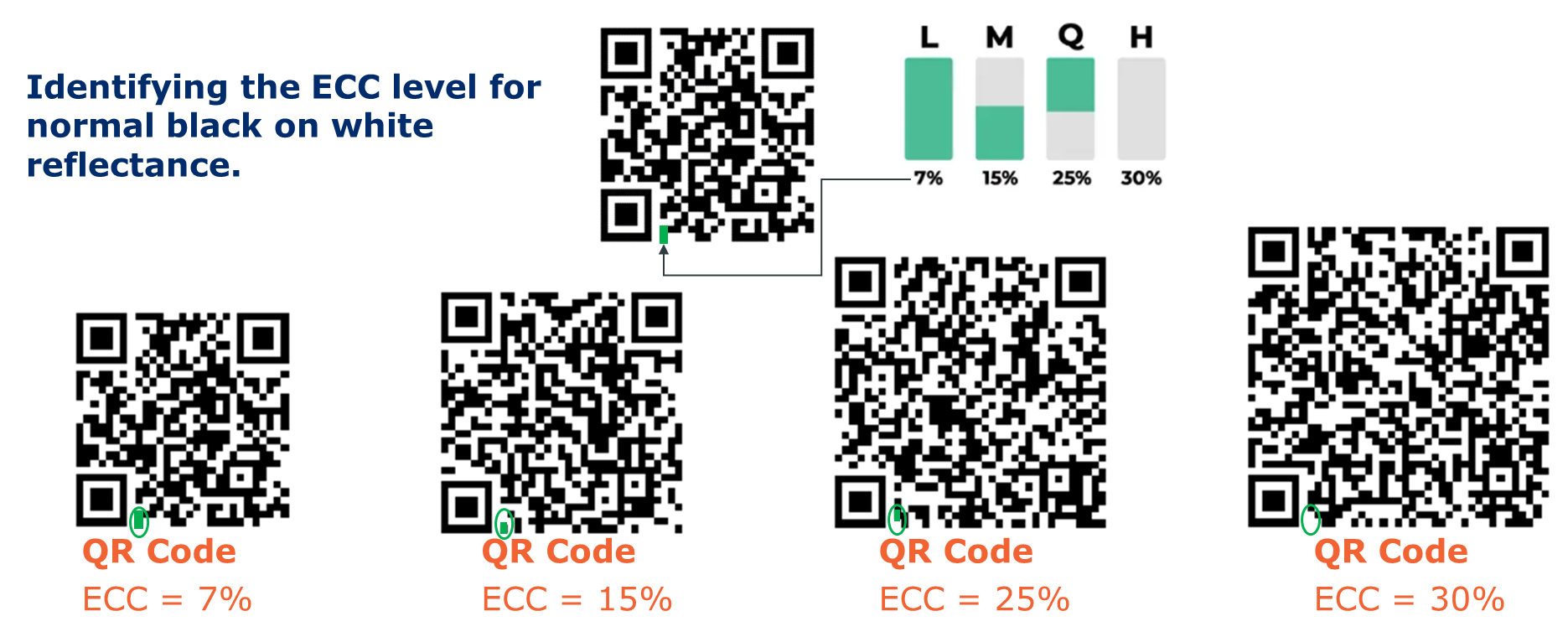

Adjusting error correction level

Choose the appropriate level based on the required error correction for the specific use case. Higher error correction levels add redundancy but increase the size of the barcode, therefore the impacts on the printing, scanning and packaging need to be considered. GS1 DataMatrix, Data Matrix and QR Code use Reed Solomon error correction (ECC).

- Data Matrix ECC is determined by the code size and the remaining storage capacity, The ECC is automatically included and is typically 30% of the barcode.

- QR Code ECC can be selected manually (i.e., L, M, Q and H). A higher error correction level can mean less storage capacity if there is 2D barcode size constraint.

Low: 7%

Medium: 15%

Quartile: 25%

High: 30%

In summary, the ECC in GS1 DataMatrix, Data Matrix and QR Code is a critical feature that enhances the reliability and robustness of these 2D barcodes over linear barcodes. Users can tailor the QR Code error correction level to suit their specific needs, ensuring optimal performance in various applications.

Adjusting X-dimension and Quiet Zone

In 2D barcodes, the X-dimension refers to the size of the individual modules that make up the barcode. In 2D barcodes, the modules are most commonly squares or dots. Smaller modules can result in a more compact barcode but making them too small can prevent reliable scanning. The GS1 Application Standard for Retail POS sets the ranges for acceptable module X-dimension size to enable reliable decoding of GS1 DataMatrix, Data Matrix and QR Codes in the retail environment. See GS1 General Specifications:

- Symbol specification table 1 addendum 2 for 2D barcodes for trade items scanned in general retail POS and not in general distribution.

- Symbol specification table 3 addendum 1 for 2D barcodes for trade items scanned at general retail POS and in general distribution.

As noted in the GS1 General Specifications the X-dimensions for 2D barcodes are 1.5 times the equivalent X-dimensions allowed for the linear barcode.

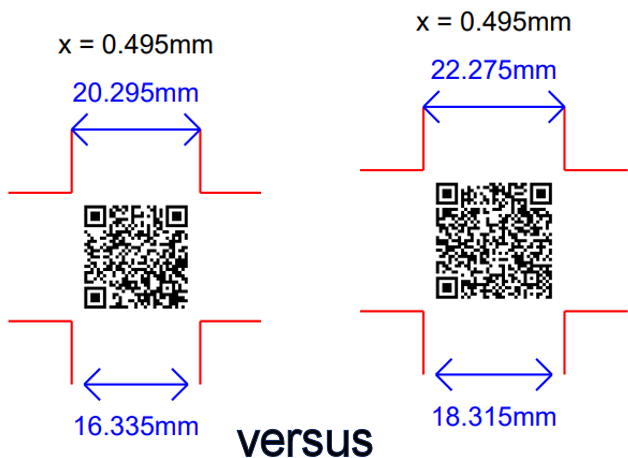

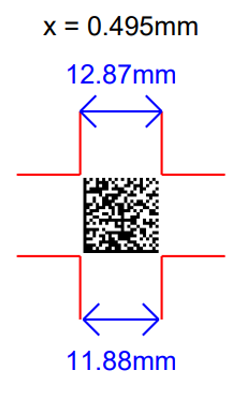

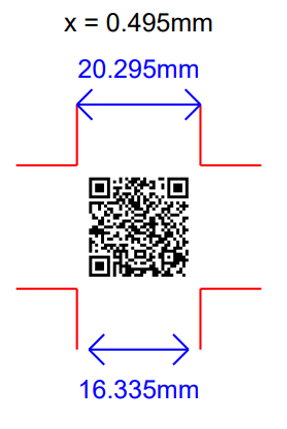

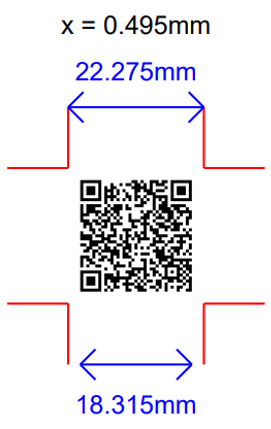

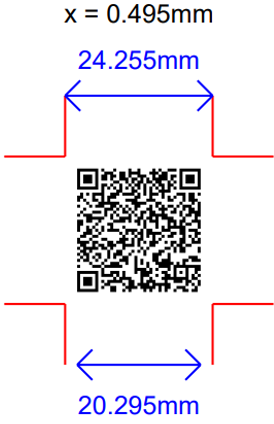

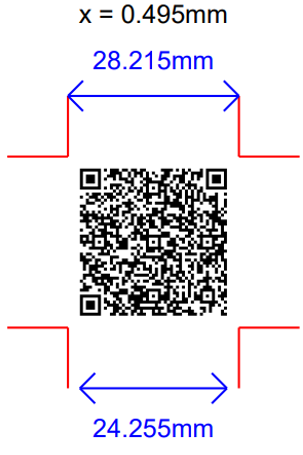

The Quiet Zone is the empty margin around all four sides of a 2D barcode. An adequate Quiet Zone is necessary for the 2D barcodes quick identification on packaging, proper scanning and to avoid interference that will prevent the reader from identifying the barcode. For GS1 DataMatrix and Data Matrix, the Quiet Zone is equal to the X-dimension on all four sides. For QR Code, the Quiet Zone is 4 times the X-dimension on all four sides.

For example, if an X-dimension of 0.495 mm (0.019 Inches) was used, the minimum Quiet Zone surrounding a GS1 DataMatrix or Data Matrix would be 0.495 mm (0.019 inches). For QR Code, it would be four times the X-dimension, 1.980 mm (0.078 inches).

See the GS1 General Specifications symbol specification table 1 - Trade items scanned in general retail POS and not general distribution.

To assist with visualising the 2D barcode size GS1 has created a GS1 Retail 2D barcode size estimator. .

Use of images, colour and other modifications in 2D barcodes

Some brand owners wish to modify the barcodes on products to incorporate images, colours, shapes or other elements they believe are more appealing to those looking at the product. This is especially prevalent with QR Codes used for marketing and consumer engagement applications. Ideal 2D barcodes have highly contrasting light and dark modules, such as black and white, feature a perfect grid using even, square modules, are in no way shortened or cut off and do not have their error corrections compromised. If proceeding with the use of 2D barcodes with modifications like what has been mentioned, it is critical to have each unique barcode verified in accordance with ISO/IEC 15415 and the relevant symbology standard to determine the barcode’s quality grade and compliance with the GS1 General Specifications requirements.

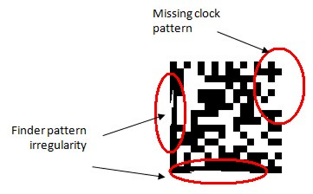

The following areas are most frequently impacted by modifications that lead to issues with barcode performance. For details on the quality assessment see 7.2.1. For further information on the use of colours and other aesthetic modifications please see the GS1 2D Barcode Colour & Quality Guide.

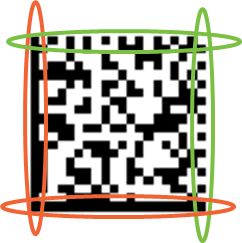

Finder pattern: Each barcode has a specific pattern that barcode readers look for to determine that what is in its field of view is a barcode and what type of barcode it happens to be. When these patterns are distorted or modified, it will become difficult for barcode scanner solutions to identify and decode the barcode.

- GS1 DataMatrix and Data Matrix uses an “L” pattern

Alignment + clocking pattern

Figure 4-17 Example of the Data Matrix finder pattern - QR Code uses three square structures in its corners Alignment + clocking pattern

Figure 4-18 Example of the QR Code finder pattern

- GS1 DataMatrix and Data Matrix uses an “L” pattern

Quiet Zone: The Quiet Zone is the empty space that surrounds all four sides of a 2D barcode. This space helps barcode readers to locate the barcode’s finder pattern and begin to process the information. Removing the quiet zone or putting graphics, colours or other ‘noise’ in the Quiet Zone space can harm barcode performance.

- GS1 DataMatrix and Data Matrix uses one X-dimension (size of one module or square) for the Quiet Zone

Figure 4-19 Example of the Data Matrix Quiet Zone - QR Code uses four X-dimensions (size of one module or square) for the Quiet Zone

Figure 4-20 QR Code Quiet Zone example

- GS1 DataMatrix and Data Matrix uses one X-dimension (size of one module or square) for the Quiet Zone

Contrast: Use of colours with poor contrast and having more than two colours can be problematic for barcode performance as barcode readers may have difficulty determining which modules are light and which are dark. This can cause a barcode to fail. Due to the use of red light in barcode scanning and verification, using colour red for the dark modules can be highly problematic and is to be avoided.

Figure 4-21 Example of contrast Uniformity: GS1 DataMatrix, Data Matrix and QR Code are designed to be in an even grid pattern where every module is a filled in square. When the grid pattern is warped, or the modules shapes are changed (e.g., star, swirl, heart) the barcode becomes more difficult to be read correctly as the standardised, expected patterns are disrupted.

Figure 4-22 Example of grid uniformity Error correction: When images are inserted into 2D barcodes, that image is using the error correction space that would otherwise be redundantly encoding the data contained in the barcode to support improved readability. As the space used for images in the barcode increases, the likelihood that barcode will perform as intended decreases.

Note: Logos and other images are not an integrated part of the ISO/IEC 16022 and ISO/IEC 18004 technical specifications GS1 normatively references respectively for the GS1 DataMatrix, Data Matrix or QR Code encoding design. Therefore, logos and other images are technically considered as damage, since they generally sit on top of the data, blocking information. The only reason they still work is the result of Reed Solomon error correction that allows the data to be rebuilt. If the logo is too large or positioned in a way to compromise the locating feature or error correction modules, this will cause a decode failure.

Figure 4-23 Example of ECC level indicator Colour: Barcode scanners and verification systems are often illuminating the barcode and substrate with red light, 660nm, therefore red, orange and yellow 2D barcodes will be difficult to decode. Human factors like colour blindness should also be considered and, in particular red-green colours are good to avoid. The best colour combination to support consistent reading is black and white.

Figure 4-24 Examples of colour versus black scanning Important: Consumer mobile devices and the barcode hardware used throughout the supply chain use different technologies and can have widely varying form factors. A barcode that works well with a consumer device may not read well at retail point-of-sale.

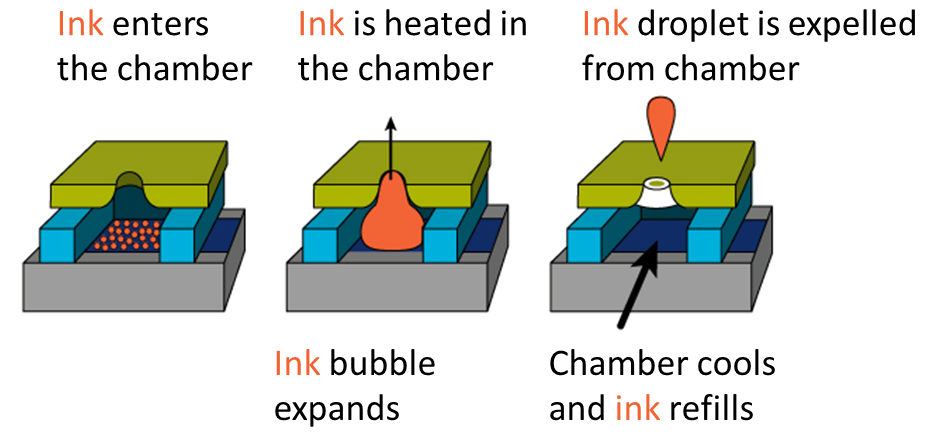

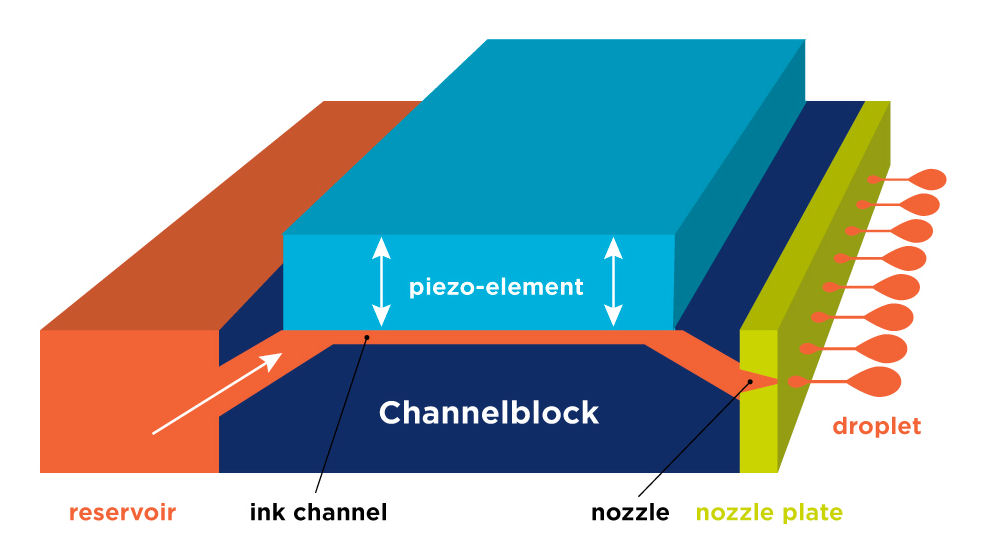

Printing, reading and processing barcodes

Printing, reading and processing the data from 2D barcodes will be discussed through the lens of brands, retailers and solution providers throughout this document. Three topics warrant further investigation: the distinction between static and dynamic printing, the security consideration of scanning 2D barcodes and the utilisation of 2D barcodes in conjunction with GS1 Digital Link URI and resolvers.

Static vs. dynamic data

The terms static and dynamic are used widely across different applications. Generally, the term “static” is used to describe things that are consistent and remain the same, while “dynamic” represents items that are able and expected to change. The GTIN and some of the data typically associated with it are static, meaning they are consistent data and are the same across all individual units of a specific trade item. Additional static data such as the ingredient list and regulatory information can be printed on the package or stored in master data and shared via systems like the GS1 Global Data Synchronisation Network™ (GDSN®).

The use of additional data on packaging increases the use of dynamic data (e.g., batch/lot number, expiration date, serial number), which can vary across instances of the trade item. For example, a lot number on a tube of toothpaste can be associated to the production date, manufacturing location and even a specific production line. A serial number on a seafood item could be associated with information about the waterway and fishing method. This data can be used for B2B purposes, facilitating traceability or targeted product recalls. With GS1 Digital Link, a web link (URL) with dynamic data can be encoded in the data carrier that links to a webpage specific to the lot or serial number. EAN/UPC barcodes can only accommodate static data while 2D barcode like GS1 DataMatrix or QR Codes can use dynamic data.

Dynamic data needs to be printed, stored, shared and processed differently than static data. For use cases, such as with food items, the static GTIN in a barcode and nutritional information may arrive at the manufacturing plant pre-printed by packaging suppliers. Dynamic data such as expiration dates and batch/lot codes is usually printed on demand at the plant or production line. As more dynamic attribute data is encoded into data carriers on packaging, brand owners and manufacturers will need to adapt their processes.

2D barcodes with static data

The first example in Figure 4-26 is a bottle with an EAN/UPC barcode at the bottom and a marketing consumer engagement QR Code with GS1 Digital Link URI syntax at the top of the label. There is no HRI associated with the QR Code because the brand owner intends the QR Code only for consumer engagement, not the point-of-sale (POS). The same GTIN is used in the EAN/UPC and 2D barcode with no additional data. This example is what we would call static data, wherein the label was produced ahead of time and then is applied at the production line. The data in the barcodes remains static across all packages. Without changes to the barcode or product packaging, the experience linked to through the QR Code with GS1 Digital Link URI can be updated by the brand owner.

2D barcodes with dynamic data

Figure 4-27 is dynamic data in a fresh food use case, where there is a need to track a product with an expiration date and batch/lot number to help with food safety. In this example with a GS1 DataMatrix, the expiration date and a lot number are being printed and applied to the packaging at the moment of production. This is also known as on demand or dynamic data printing.

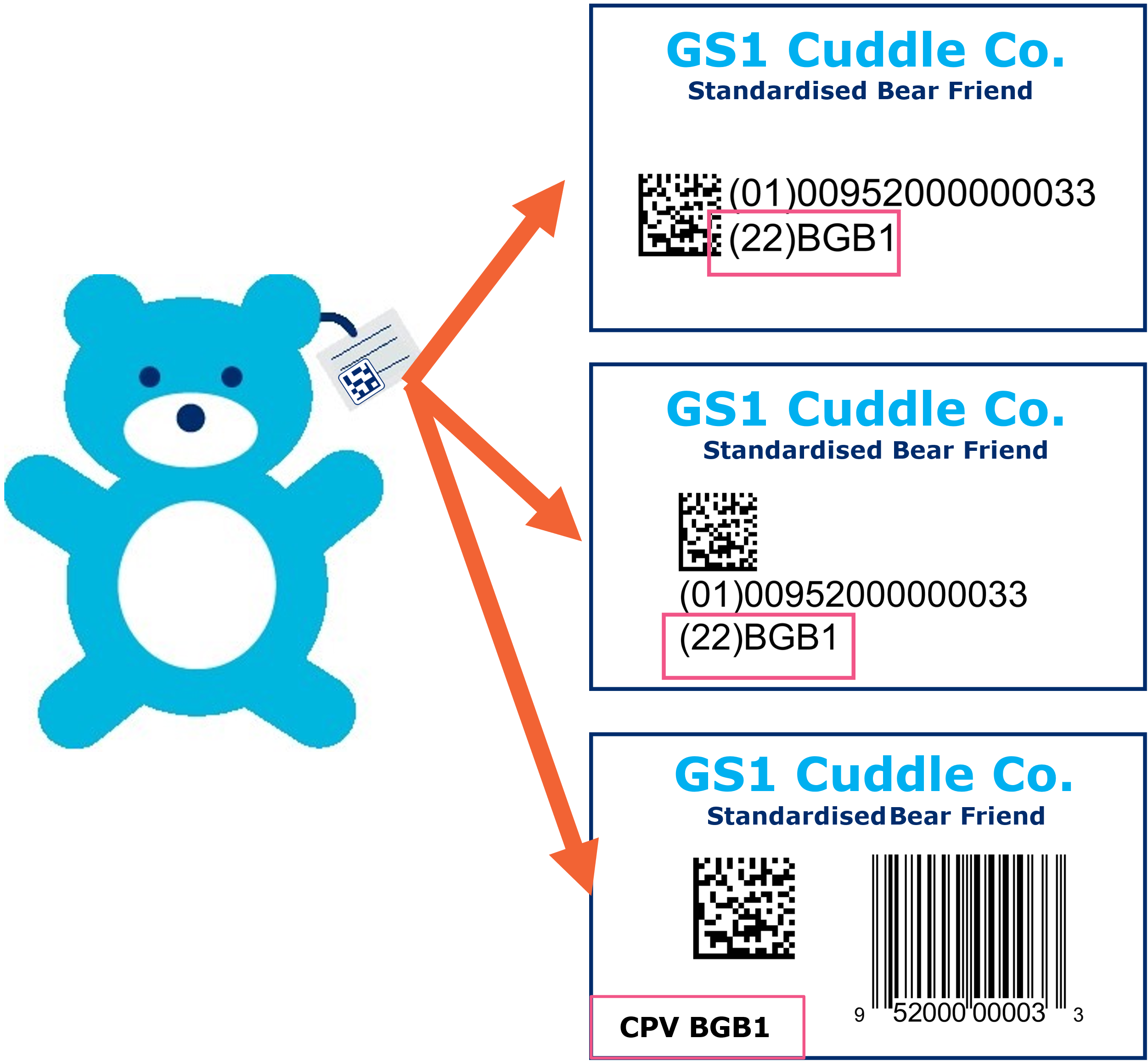

As another dynamic data example, a serial number is included as the brand owner wants to uniquely identify every individual instance of a product. This approach works well for applications such as apparel where there is a GTIN and serial number in a RFID tag or 2D barcode. Implementation can occur either during the apparel item's production process or post-production, such as at a service bureau facility, see Figure 4-28.

In the final example shown in Figure 4-29, the label is a preprinted QR Code with GS1 Digital Link URI with GTIN and serial number in it. This is an interesting solution option because this is not dynamic printing at the production line. This dynamic printing occurred before the production processes. When the label with the serial number is applied and goes along the production line, the camera that is inspecting the QR Code reads the barcode and stores the serial number in a database. Until the scanner reads the QR Code with the serial number and sends the data to the database, the product is not visible to the production environment.

2D barcode security

Can 2D barcodes be used by bad actors to “hack” or exploit the consumer scanning the QR Code? Since QR Codes can carry web links then hackers can exploit their capability just like they do in emails. This practice is known as Quishing, an amalgamation of QR Codes with Phishing. Phishing is where a bad actor attempts to get personal information often through email. These Quishing QR Codes would likely be in an email or on a public wall, not encoded in a brands’ or retailers’ QR Codes powered by GS1 Digital Link URI.

QR Codes are neither inherently safe nor unsafe. They are neither secure nor insecure. It is the software used to scan them and the behaviour of the user that will determine whether scanning a QR Code leads to ‘good’ information or ‘bad’.

For the consumer or anyone that uses a smart device to scan a bad actor’s QR Code the same warnings and protocols that we use for email phishing still apply. It is often difficult to identify where the URL will link us to, but the brand or retailer can help by selecting a domain name that will resonate with and give confidence to the user. Today our digital accounts often have two factor identification, so safety nets do exist if we choose to enable them.

For some applications, the 2D barcode will contain information in addition to the product identifier

(GTIN), such as batch number, serial number or expiry date. This additional information provides even more granular identification of the product to which the 2D barcode is applied. Combined with traceability data about the product's movements, or data sharing via a common national or regional database, the 2D barcodes, similar to other GS1 barcodes that contain this granular information can be used to help prevent product counterfeiting. This is seen today in applications for pharmaceuticals, amongst other industries. Many healthcare product manufacturers prefer to randomise the serial numbers in the GS1 DataMatrix to make it more difficult for counterfeiters to guess the sequence in an attempt to make fake product seem more legitimate.

As with any implementation of web information that can be accessed by consumers, care must be taken to understand security risks and threats. While QR Codes by themselves don't pose risk, companies need to consider the same security and privacy policies they have for their brand/corporate website for their product information pages that may be linked from a QR Code. For additional information, see "Introduction to QR Codes by the U.S. Government and Security considerations for QR Codes by the Canadian government centre for cyber security and FBI QR Code Advisory (https://www.ic3.gov/PSA/2022/PSA220118).

Resolver

The term ‘resolver’ is used for any service that connects an identifier to an information source. A GS1-conformant resolver connects a GS1 identifier to one or more sources of information about the identified entity. For example, it can connect a product’s GTIN to a web page about the product, instructions and ideas for how to use the product, sustainability information and more. Likewise, it can connect an air conditioning unit to a detailed product specification, its installation and service history. In healthcare applications, it could be pharmaceutical information for patients, distinct from that for clinicians, all in the correct language and according to the local regulations, as well as electronic Product Information Leaflets (ePIL) Summaries of product characteristic (SmPC) and electronic Instruction for Use (eIFU) for healthcare products.

By following the standard, GS1-conformant resolvers can operate as a network with no single point of failure. Information about a product, asset or location remains within the data owner’s own system with the resolver network acting as a discovery service. The GS1 Resolver Test Suite can determine if a GS1-conformant resolver correctly connects GS1 identifiers to their associated online resources, to confirm that the resolver conforms to the standards.

GS1 Member Organisations, solution providers and brand owners are all encouraged to operate resolvers according to their own business practices, but the input is always a GS1 Digital Link URI. Applications can query any resolver in the network with a common set of commands and expect a common set of responses. In healthcare applications, refer to local or jurisdictional regulatory validation systems requirements and good practice quality guidelines, sometimes known as GxP, that further govern the type of content to which the scan is directed,

To learn more about revolvers please visit the GS1-Conformant Resolver Standard.

Implementation guidance for brands and manufacturers

Whether exploring 2D barcodes for the first time or modifying an existing implementation, those producing products have a great deal to consider. Section 5 provides guidance on determining where to start, who to involve, what type of data to include in which barcode, where to put the barcode and additional details to support a successful 2D barcode implementation at retail point-of-sale (POS).

This section is intended to be used by brand owners, Global Trade Item Number (GTIN) allocators, manufacturers and retailers with private label or fresh products labelled by contract manufacturers. Throughout this guideline, these parties are referred to as brands.

Note: The brand manufacturer/owner-specific guidance in section 5 expands on the general information found in section 4. Retailers seeking information on enabling 2D barcode capabilities at POS and in-store barcode production use cases will refer to section 6.

Brand manufacturer roles in 2D implementation

When a brand manufacturer is considering the use of GS1 2D barcodes on a trade item, different areas of the organisation will need to be involved in guiding the strategic and tactical efforts needed to introduce these barcodes or transition from existing barcodes. The table below outlines some key roles that may need to be involved, depending on numerous factors including the specific implementation, the size of the organisation and the speed with which 2D will be introduced. The table is a guide to consider and not comprehensive. Every organisation will need to tailor their project(s) to fit their specific requirements or constraints.

When to start transitioning to 2D barcodes

Each company will have their own, unique business needs that will determine which product or products will first transition to using a 2D barcode and what that barcode will contain. For guidance on determining what to include in the barcode, see section 5.4.

For an interactive roadmap to navigate key business questions and considerations essential for successful 2D barcode implementation, see the 2D Barcode Implementation Journey: A Practical Guide for Retailers and Brand Owners.

Important: Linear barcodes, such as EAN/UPC and the GS1 DataBar retail POS family, will still be available for use. GS1 standards will continue to allow the use of linear barcodes. Exceptions may occur if regulatory or legal requirements mandate only the use of a 2D barcode.

Common reasons to begin a transition to 2D barcodes

The following are the most common reasons why the transition to 2D barcodes begins.

- Consumer engagement opportunity: Whether it is sharing recipe ideas, promotions, handling instructions, certifications connecting consumers to social media or all the above, brand owners need improved ways of connecting consumers to experiences through a product and its packaging. Fulfilling this need to create consumer engagement experiences is a key reason many companies transition to 2D barcodes.

- Package design constraints: Limited space on products and packaging for design elements, consumer engagement, declarations or other information lead many companies to explore the use of 2D barcodes to consolidate multiple barcodes to free up space, extend packaging online, and provide transparency to consumers and supply chain stakeholders.

- Regulatory requirements: For some product types, regulatory requirements may be in place that only 2D barcodes can support. Many times, these regulatory requirements overlap with other business drivers for transitioning to 2D barcodes. For information on using 2D barcodes to support regulatory requirements, contact your local GS1 Member Organisation.

- High-risk product categories: Certain product types have a higher need for additional data and/or consumer transparency, separate from regulatory compliance requirements. Many brand owners will prioritise their 2D barcode migration based on which products can most benefit from more data encoded in the barcode or linked to an online experience. Products more likely to be subject to recalls, counterfeiting, having expired product on-shelf are some examples of what brand owners may begin with.

- Supply chain or retail need: 2D barcodes are capable of encoding data that can support a wide variety of information to support supply chain and retail needs that also work towards keeping consumers safe and satisfied. Product types that most benefit from data such as batch/lot numbers, dates, country of origin, variable measure information or serial numbers are commonly prioritised. This additional data can support recall management, traceability, inventory availability and management, authenticating returns and more.

- Sustainability or circularity activities: The information encoded directly into a 2D barcode, along with the information 2D barcodes can direct users to online, can support sustainability and circularity use cases that are key business drivers throughout many markets and may be tied to regulatory activity. Preventing food waste, enabling easier recycling practices and sharing certifications and other details relating to sustainability are some of the 2D barcode transition drivers in this area

For information on what information to put into a 2D barcode to support specific use cases, see section 5.4.

Determining which products to start with

While 2D barcodes using GS1 standards can be introduced at any time, certain scenarios may make the transition to 2D barcodes more manageable.